PUF Panel Portable Storage Cabin — Fast, Secure, Energy Efficient On Site Space

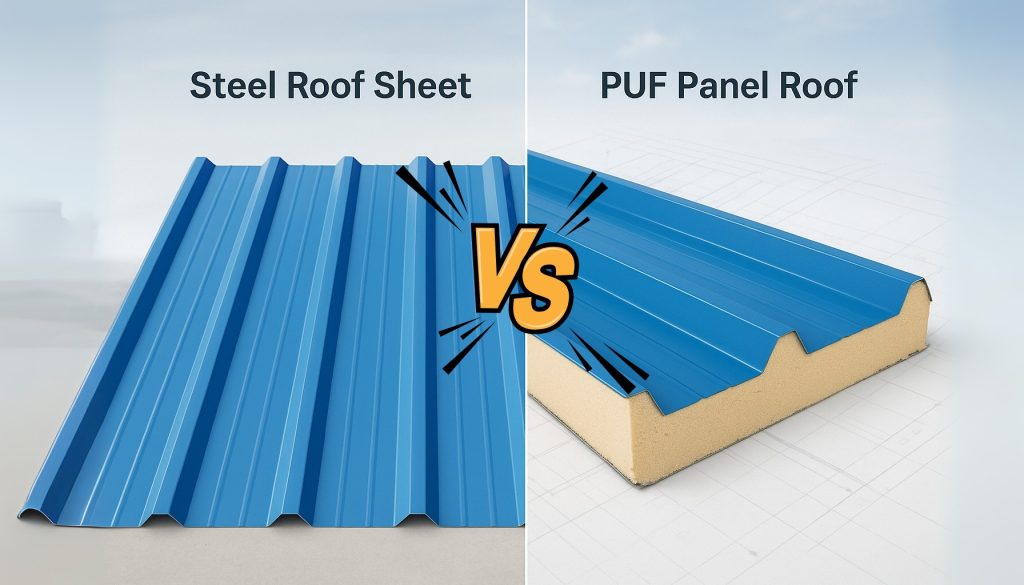

PUF Panel Portable Storage Cabin PUF Panel Portable Storage Cabin — Fast, Secure, Energy Efficient On Site Space In fast-moving projects and dynamic operations, teams need secure, relocatable space that can be deployed in days—not weeks. That’s exactly where PUF panel cabins excel. Built for reliability, flexibility, and energy efficiency, they deliver the ideal balance of protection and performance for assets, documents, tools, and packaged goods across construction sites, factories, institutions, and event venues. Whether the requirement is a compact guard-side store or a scalable complex of linked units, PUF panel cabins transform storage from a stopgap into a strategic advantage—especially for businesses seeking high-quality, long-life solutions in the realm of portable storage. Modern facilities demand more than a basic shed. They need temperature stability, controlled interiors, and robust weatherproofing to protect inventory and improve worker comfort. PUF panel technology provides a high-insulation envelope that keeps interiors cooler in hot climates and more stable year-round, outperforming traditional sheet-metal or bare MS cabins. This translates to lower HVAC loads, fewer condensation issues, and meaningful lifecycle savings. Because PUF panel systems are precision-fabricated and modular, they assemble quickly with minimal disruption—making them ideal for expanding operations, seasonal peaks, or rapid mobilization scenarios, particularly where mobile storage units have to be installed, relocated, or expanded efficiently. Compared to conventional sheds, PUF panel cabins offer cleaner interiors, superior thermal performance, and better acoustic comfort, which is critical when a storage cabin doubles as a store-cum-work area. The insulated wall and roof panels reduce energy consumption while enhancing durability and hygiene—benefits that matter for pharmaceuticals, food packaging, spares, or sensitive equipment. They also integrate seamlessly with racking, power points, ventilation, and security upgrades, making them a smarter long-term choice than ad-hoc structures. For teams evaluating portable storage or portable storage units, PUF panel cabins provide a compelling upgrade path without sacrificing speed or flexibility. Maks Engineering brings a specialist edge to every project. Expert installation ensures clean finishes and the airtight joints essential for thermal performance and condensation control. Attention to detail at panel junctions, door interfaces, and penetrations prevents common failure points, extending service life and reducing maintenance. The result: a tighter, safer, and more efficient storage cabin that performs in demanding environments. With responsive after-sales support and the capability to tailor layouts, insulation thickness, and fittings to use-case and climate, Maks Engineering delivers end-to-end confidence—from site survey to commissioning—so operations can scale mobile storage units with minimal friction and maximum return on investment. What Is a PUF Panel Portable Storage Cabin? A PUF Panel Portable Storage Cabin is a factory-built, relocatable enclosure engineered for reliable, on-site storage with superior thermal and structural performance. At its core, it combines a rugged steel frame with high-performance insulated sandwich panels for walls and roof, typically using PUR/PIR cores and exterior PPGI/PPGL sheets for long-term weather protection. This assembly sits on a durable, load-rated floor designed to handle racking, drum pallets, and frequent foot traffic—making it an ideal upgrade over ad-hoc sheds or repurposed containers when comfort, efficiency, and clean interiors matter for a modern portable storage cabin. Unlike a generic storage container cabin or basic shipping container storage, a PUF-panel solution is purpose-built for controlled interiors and fast deployment. The insulated envelope cuts heat ingress, reduces condensation, and keeps the storage environment stable, while the modular construction allows quick assembly, easy repairs, and straightforward expansion. For teams that need flexible capacity without compromising on finish or performance, this approach offers the best of both worlds: the speed and mobility of portable storage with the energy-saving advantages of insulated construction seen in high-spec industrial cabins and portable storage containers. Core Benefits of PUF Panel Portable Storage Cabin: High insulation for cooler interiors and lower energy bills The PUR/PIR core in the sandwich panels delivers excellent thermal resistance, minimizing HVAC loads and maintaining consistent temperatures. This is especially important where sensitive materials, spares, or documents are stored, and where portable storage needs to double as a store-cum-work area. Robust, weather-resistant shell The combination of steel framing and PPGI/PPGL exterior skins forms a tough barrier against rain, dust, and UV exposure. Compared to bare conversions often used for shipping container storage, the integrated insulated build mitigates condensation and improves interior durability, enhancing the long-term value of the portable storage cabin. Quick setup, minimal site disruption Precision-fabricated panels lock together cleanly, enabling rapid installation with reduced noise, debris, and downtime. This speed is a major advantage over conventional masonry or retrofitting a storage container cabin, allowing operations to scale movable storage units on tight timelines. Modular, relocatable, and expandable design The panelized system makes it easy to add doors, windows, shelving, and extra bays as needs evolve. Cabins can be dismantled, relocated, or extended—ideal for dynamic projects that rely on portable storage containers or plan phased capacity increases with multiple movable storage units across sites. In summary, a PUF Panel Portable Storage Cabin blends the practicality of portable storage with the performance of insulated construction: a clean, efficient, and professional-grade solution that outperforms improvised sheds and typical shipping container storage when thermal comfort, speed, and scalability are critical. Where These Cabins Shine (Use-Cases) Purpose-built to balance durability, thermal performance, and speed of deployment, PUF panel cabins thrive wherever operations demand secure, flexible space that can scale quickly. From fast-paced construction to organized retail backrooms, these units transform ad‑hoc storage into a clean, efficient, and professional setup—whether the need is short‑term capacity, phased projects, or multi-site rollouts using temporary storage containers. Construction On active job sites, downtime is costly and security is critical. A PUF panel storage cabin keeps tools, consumables, spares, and documents organized and protected from dust, moisture, and heat. Crews gain faster access, fewer losses, and better stock control—all while enjoying the mobility of mobile storage units that can be relocated as the site evolves. For phases that need extra rooms in a hurry, choose rapid-deploy portable storage or plug and play portable storage units to keep schedules on track. Manufacturing Production floors depend on reliability. Position maintenance stores, line side inventory, and MRO spares inside an insulated storage cabin to reduce temperature swings

PUF Panel Portable Storage Cabin — Fast, Secure, Energy Efficient On Site Space Read More »