Clean Room Doors

Clean Room Doors

When it comes to controlled environments, every detail matters, and clean room doors are among the most critical components. A cleanroom is specifically designed to limit contamination and maintain a sterile atmosphere, but this environment can only function effectively if the entry points are engineered with the same precision. Unlike conventional doors, a cleanroom door is not just an entryway—it is a barrier that safeguards sensitive processes from dust, microbes, and temperature fluctuations. This makes the choice of a reliable clean room door manufacturer essential for industries where hygiene and safety are non-negotiable.

One of the most advanced solutions available today is the use of PUF panel technology in clean room door design. PUF (Polyurethane Foam) Panels are known for their exceptional thermal insulation, high durability, and smooth, hygienic surfaces that are resistant to bacterial growth. Unlike traditional materials that may warp, corrode, or accumulate contaminants over time, PUF panel-based clean room doors maintain structural integrity and sterility even in demanding industrial environments. This innovation not only improves energy efficiency but also ensures compliance with international cleanroom standards.

Industries that require strict contamination control increasingly rely on pharmaceutical clean room doors made from PUF panels. In pharmaceutical production units, they help maintain sterile conditions for drug formulation and packaging. In food processing facilities, they prevent cross-contamination while preserving temperature-sensitive products. Research laboratories and biotechnology centers benefit from their airtight sealing and resistance to microbial infiltration. Even hospitals and healthcare centers, particularly in operating rooms and diagnostic labs, depend on these doors to maintain sterile zones critical to patient safety.

By combining precision engineering with sustainable materials, PUF-based clean room doors offer the perfect balance of strength, insulation, and hygiene. At MAKS Engineering, our focus as a leading clean room door manufacturer is not just to supply doors but to deliver complete solutions that enhance efficiency, reduce risks, and stand the test of time.

What Are Clean Room Doors?

Clean room doors are specialized entry systems designed to maintain the integrity of controlled environments such as laboratories, pharmaceutical units, research facilities, and food processing plants. Unlike regular doors, a cleanroom door is engineered with precision to minimize the risk of airborne particles, microbial infiltration, and unwanted temperature variations. They form a vital component of the overall cleanroom architecture, ensuring that every entry and exit upholds the stringent hygiene and safety standards of the facility.

The role of clean room doors goes far beyond access control. They act as a shield against contamination, maintaining proper air pressure differentials and supporting insulation to preserve temperature-sensitive environments. For industries where even the smallest particle or fluctuation can compromise product quality or patient safety—such as pharmaceuticals, biotechnology, and healthcare—the choice of the right pharmaceutical clean room door becomes critical.

Another key function of these doors is insulation. High-quality materials like PUF (Polyurethane Foam) Panels are often used in modern clean room door design to enhance thermal and acoustic insulation. This helps not only in maintaining a sterile atmosphere but also in reducing energy consumption, making them a practical and sustainable solution. As a result, businesses increasingly rely on an experienced clean room door manufacturer that can provide doors engineered with advanced technologies to meet international cleanroom standards.

Depending on the application, clean room doors come in several types:

- Swing Doors – The PUF core reduces heat transfer, maintaining stable temperatures inside laboratories. This is particularly critical in research environments, cleanrooms, and medical facilities where even minor fluctuations can affect results.

- Sliding Doors – Perfect for spaces where efficient use of floor area is important. These provide smooth, hygienic operation while maintaining cleanroom conditions.

- Hermetically Sealed Doors – Specially designed for high-level cleanroom environments, these doors provide maximum airtightness, preventing any possibility of contamination leakage.

In essence, clean room doorsr ae not just functional components—they are critical to ensuring compliance, safety, and efficiency across industries. The right cleanroom door safeguards sensitive operations, enhances productivity, and reduces long-term risks associated with contamination.

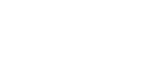

Key Features of PUF Panel Clean Room Doors

Modern industries demand precision, hygiene, and reliability, and that’s exactly what PUF-based clean room doors deliver. Designed with cutting-edge materials and engineered to meet the strictest standards, these doors combine superior functionality with durability. As a trusted clean room door manufacturer, MAKS Engineering focuses on creating solutions that not only meet but exceed industry expectations. Below are the key features that make PUF panel-based clean room doors stand out:

1. Airtight Sealing to Block Contaminants

One of the most crucial requirements of a pharmaceutical clean room door is its ability to create a perfectly sealed environment. PUF panel cleanroom doors are designed with airtight sealing systems that effectively block dust, microbes, and airborne contaminants. This ensures that the sterile conditions inside the facility remain uncompromised, supporting the integrity of critical processes.

2. Thermal & Acoustic Insulation

Advanced clean room door design must account for insulation. PUF panels provide excellent thermal resistance, helping maintain consistent temperatures in cold storage units, laboratories, and pharmaceutical production rooms. At the same time, they offer sound insulation, reducing noise pollution in sensitive environments such as hospitals and research labs. This dual benefit makes them a preferred choice across multiple industries.

3. Anti-Bacterial & Moisture-Resistant Surfaces

The smooth, non-porous surfaces of PUF-based clean room doors are inherently resistant to bacterial growth and moisture absorption. This not only makes cleaning and disinfection easier but also minimizes the risk of microbial contamination. For pharmaceutical, healthcare, and food-processing facilities, this feature is vital for meeting regulatory hygiene standards.

4. Long Life & Low Maintenance

Durability is another reason industries choose PUF-based clean room doors over conventional options. Resistant to corrosion, warping, and wear, these doors offer a long service life while requiring minimal upkeep. For organizations seeking cost-effective, long-term solutions, the investment in a pharmaceutical clean room door ensures reliability without frequent repairs or replacements.

5. Customizable Sizes and Finishes

Every cleanroom has unique requirements, and flexibility in clean room door design is essential. PUF panel cleanroom doors can be customized in terms of size, finish, color, and hardware to perfectly suit the functional and aesthetic needs of a facility. Whether it’s a compact laboratory door or a large industrial entryway, customization ensures the door integrates seamlessly with the overall architecture.

PUF panel clean room doors represent the perfect balance of hygiene, insulation, and durability. With their airtight sealing, insulation benefits, anti-bacterial properties, and customizable options, they are the go-to solution for industries where precision and cleanliness are mission-critical. Partnering with an experienced clean room door manufacturer like MAKS Engineering ensures that every facility gets doors tailored to its exact needs, built to deliver performance for years to come.

Industries That Benefit from PUF Panel Clean Room Doors

The demand for high-quality clean room doors continues to rise across industries where hygiene, safety, and controlled environments are non-negotiable. As a specialized clean room door manufacturer, MAKS Engineering delivers advanced PUF panel-based solutions that cater to diverse sectors. These industries rely on precise clean room door design not just for functionality, but also for compliance with international safety and quality standards. Let’s explore the key industries that benefit most from PUF-based clean room doors.

Pharmaceuticals & Biotechnology – Maintaining Sterile Environments

In pharmaceutical production units and biotech facilities, maintaining sterility is mission-critical. A pharmaceutical clean room door ensures that manufacturing and packaging processes remain free from contamination. PUF panel doors provide airtight sealing, smooth surfaces for easy sanitization, and thermal insulation to protect temperature-sensitive formulations. Their role in preventing cross-contamination is indispensable, making them a standard in Good Manufacturing Practice (GMP) compliant facilities.

Food & Beverage Processing – Ensuring Hygiene and Temperature Control

The food and beverage sector requires strict adherence to hygiene protocols. PUF-based clean room doors are ideal for cold storage units, production areas, and packaging zones. Their antibacterial surfaces, resistance to moisture, and insulation properties ensure that food products remain safe and fresh. With precise clean room door design, manufacturers can minimize spoilage, reduce energy loss, and guarantee compliance with food safety regulations. You can read our dedicated blog on Cold Room Doors that is also used in such industries.

Healthcare & Hospitals – Safeguarding Patient Safety

In hospitals and healthcare facilities, particularly in operating rooms, ICUs, diagnostic labs, and pathology centers, clean room doors play a crucial role in patient safety. These doors prevent airborne pathogens from entering sterile zones, while also offering acoustic insulation to maintain a calm, controlled environment. PUF panel-based pharmaceutical clean room doors are widely used in healthcare settings for their hygienic properties, durability, and ease of maintenance. Also read our detailed blog on Operation Theatre Doors made of PUF Panels that is widely used in healthcare and hospitals.

Research Laboratories & Electronics – Contamination and Dust Control

Research facilities and electronics manufacturing units demand dust-free environments for accurate results and defect-free production. A properly engineered cleanroom door ensures minimal particle infiltration, protecting delicate experiments and sensitive electronic components. The airtight sealing and smooth, easy-to-clean design of PUF panel doors make them indispensable in these high-precision industries.

Across all these industries, the choice of the right clean room door manufacturer directly impacts operational efficiency, compliance, and safety. By combining advanced PUF technology with customizable clean room door design, MAKS Engineering provides solutions tailored to the unique needs of pharmaceuticals, food processing, healthcare, and research facilities.

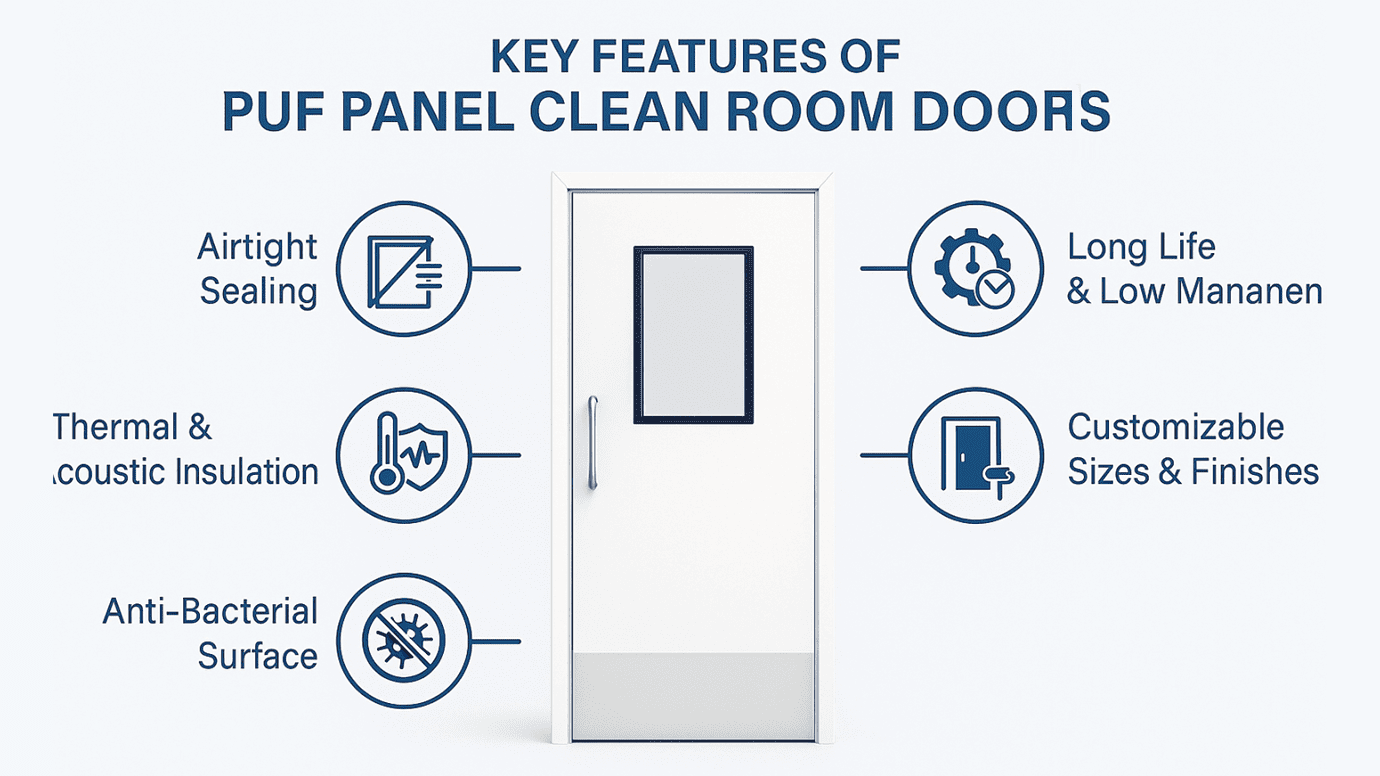

Comparing PUF Panel Doors with Regular Doors

When it comes to controlled environments, not all doors are created equal. Traditional doors may be suitable for general use, but industries that demand precision and hygiene require specialized solutions. This is where PUF panel-based clean room doors stand out. By combining superior materials with advanced clean room door design, they offer unmatched performance compared to regular doors. Let’s examine the key areas where PUF panel clean room doors outperform conventional options.

Energy Efficiency

Regular doors often fail to provide adequate thermal insulation, leading to energy losses in temperature-sensitive facilities such as cold storage units, laboratories, and pharmaceutical plants. In contrast, PUF panel pharmaceutical clean room doors are engineered with high-density insulation that helps maintain consistent temperatures. This not only ensures product safety but also reduces energy consumption, making them a sustainable and cost-effective choice.

Durability

Standard doors are prone to wear, warping, and corrosion over time, especially in demanding industrial environments. PUF panel-based clean room doors, however, are designed for strength and longevity. Their resistance to moisture, chemicals, and bacterial growth ensures a longer service life with minimal maintenance. For organizations seeking reliability, partnering with a trusted clean room door manufacturer guarantees doors built to endure years of heavy use without compromising performance.

Compliance with Clean Room Standards

One of the biggest drawbacks of conventional doors is their inability to meet strict contamination control requirements. Gaps, porous materials, and poor finishes make them unsuitable for sterile environments. On the other hand, PUF panel cleanroom doors are specifically designed to meet international cleanroom and GMP (Good Manufacturing Practice) standards. Their airtight sealing, smooth antibacterial surfaces, and customizable clean room door design make them essential for industries like pharmaceuticals, healthcare, and biotechnology.

ROI (Long-Term Savings)

While regular doors may seem cost-effective initially, they often lead to higher operational costs in the long run due to frequent repairs, replacements, and energy losses. PUF panel clean room doors deliver better ROI by combining durability, energy efficiency, and reduced maintenance. The upfront investment is quickly recovered through lower energy bills, extended lifespan, and fewer disruptions to critical operations.

The difference between standard doors and PUF panel-based pharmaceutical clean room doors is clear. Where conventional options fall short in insulation, durability, and compliance, specialized clean room doors provide unmatched performance and long-term value. Choosing a reliable manufacturer like MAKS Engineering ensures that every facility benefits from advanced clean room door design, tailored to meet the highest industry standards.

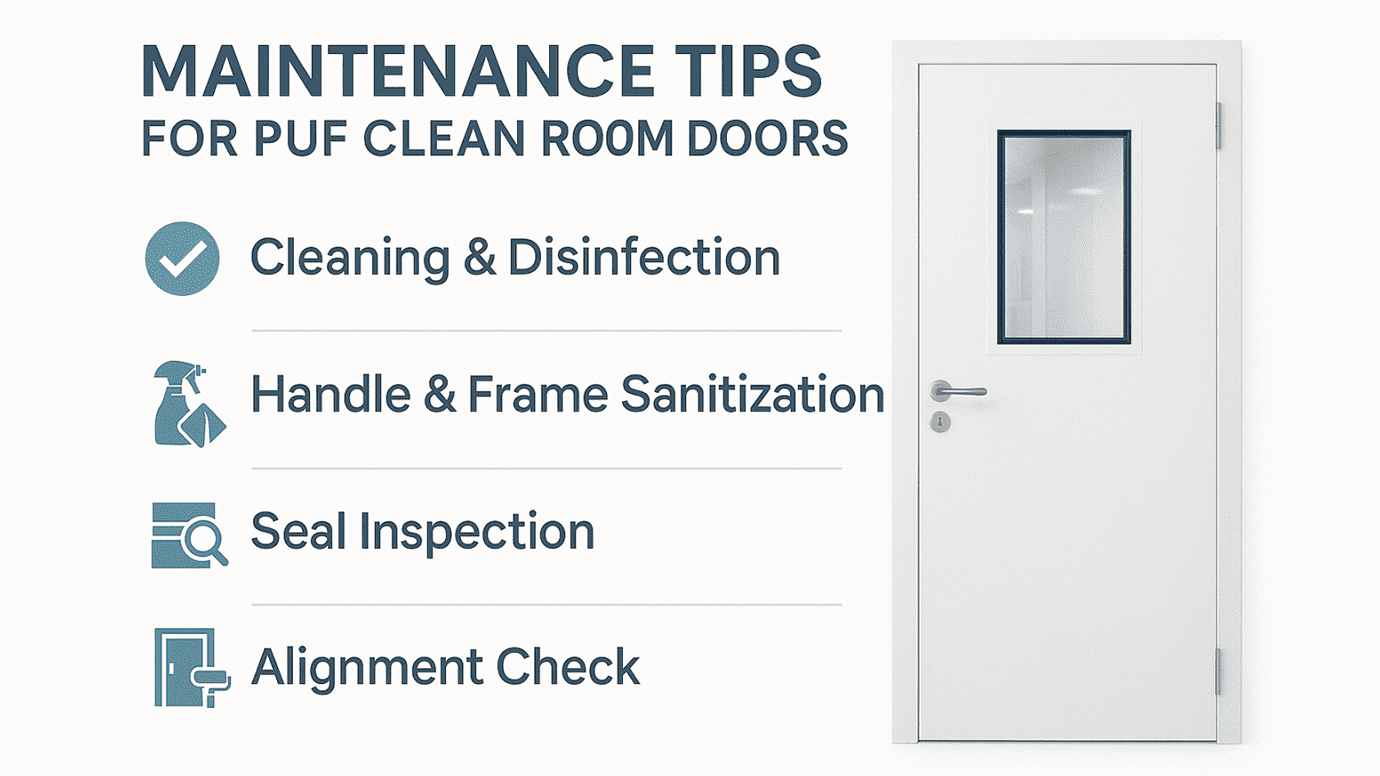

Installation & Maintenance Tips of Clean Room Doors

The performance and longevity of clean room doors depend not only on their design and materials but also on proper installation and consistent maintenance. Even the most advanced cleanroom door can underperform if it is not installed correctly or neglected during routine upkeep. As an experienced clean room door manufacturer, MAKS Engineering emphasizes both expert installation and regular maintenance to ensure that every pharmaceutical clean room door continues to meet stringent hygiene and safety standards.

Proper Sealing and Alignment During Installation

Correct installation is the foundation of an effective cleanroom system. For clean room doors, airtight sealing and precise alignment are critical to prevent the infiltration of dust, microbes, and contaminants. A poorly aligned door may create gaps that compromise air pressure differentials within the facility. Professional installation by a reliable clean room door manufacturer ensures that each door is fitted securely, with hinges, frames, and locking systems aligned for long-term airtight performance.

Cleaning and Disinfection Guidelines

Routine cleaning and disinfection are essential to maintaining the integrity of clean room door design. The smooth, non-porous surfaces of PUF panel-based cleanroom doors make them easy to sanitize using approved disinfectants. Cleaning should be carried out with non-abrasive materials to avoid damaging the protective coating. In pharmaceutical and healthcare settings, special focus should be placed on high-contact areas like handles and frames to minimize the risk of microbial spread.

Periodic Inspection for Wear & Tear

Even the most durable pharmaceutical clean room doors require periodic inspections to ensure optimal performance. Facilities should schedule routine checks for hinges, seals, handles, and alignment. Identifying early signs of wear, such as reduced airtightness or surface damage, helps avoid costly repairs and ensures compliance with international cleanroom standards. Preventive maintenance not only extends the life of the door but also reduces downtime in critical operations.

By following these installation and maintenance best practices, industries can maximize the efficiency and durability of their clean room doors. Choosing a trusted clean room door manufacturer like MAKS Engineering not only guarantees expert installation but also provides long-term support to keep your doors in peak condition. With the right approach to clean room door design, cleaning, and inspection, organizations can safeguard their sterile environments while reducing operational risks.

Why Choose MAKS Engineering for Clean Room Doors?

Selecting the right partner for clean room doors is just as important as the product itself. A reliable clean room door manufacturer doesn’t just provide doors—it delivers solutions that enhance hygiene, efficiency, and compliance for industries where precision is critical. MAKS Engineering stands out as one of India’s most trusted names in this domain, with over 15 years of expertise in designing and manufacturing advanced PUF panel products, including high-performance pharmaceutical clean room doors.

Over 15 Years of Expertise in PUF Panel Products

With decades of experience, we understand that every facility has unique requirements. Our specialization in PUF panel technology allows us to create clean room doors that excel in thermal insulation, airtightness, and hygiene. This expertise ensures that our doors not only meet industry expectations but also comply with global cleanroom standards.

Successfully Delivered Clean Room Projects

MAKS Engineering has a proven track record of delivering high-quality cleanroom solutions across diverse industries. From pharmaceutical production facilities to biotechnology labs, food processing units, and healthcare institutions, our PUF panel-based clean room doors have been integral to projects where sterility and performance cannot be compromised. Our completed projects stand as a testament to our commitment to excellence and precision.

Custom Designs Tailored to Your Needs

No two facilities are the same, and that’s why we focus on flexible clean room door design. Whether it’s swing doors, sliding systems, or hermetically sealed options, we customize every detail—from dimensions and finishes to accessories and hardware. This ensures seamless integration with your facility’s architecture while addressing its specific operational challenges.

Quick Installation and Ongoing Support

Time is critical in industries like pharmaceuticals and healthcare. That’s why MAKS Engineering offers quick, professional installation services for clean room doors, minimizing downtime and ensuring immediate usability. Beyond installation, we provide long-term support and guidance to help clients maintain their doors in peak condition, ensuring lasting performance and reliability.

At MAKS Engineering, our goal is not only to supply pharmaceutical clean room doors but also to partner with clients in creating sterile, efficient, and future-ready environments. As a trusted clean room door manufacturer, we blend innovation, quality, and customer focus to deliver solutions that stand the test of time. When you choose us, you’re choosing a team that understands the science of cleanliness and the art of engineering.

FAQs:

Q1. What are clean room doors and why are they important?

A. Clean room doors are specialized entry systems designed to maintain sterile environments by preventing contamination, temperature fluctuations, and airborne particles. Their importance lies in protecting sensitive operations in industries such as pharmaceuticals, biotechnology, food processing, and healthcare.

Q2. How does clean room door design differ from regular doors?

A. Unlike regular doors, clean room door design focuses on airtight sealing, insulation, and hygienic surfaces. They are built with materials like PUF panels to resist bacteria, moisture, and dust, ensuring compliance with international cleanroom standards.

Q3. Which industries benefit most from clean room doors?

A.PUF panel-based cleanroom doors are widely used in pharmaceuticals, biotechnology, food & beverage processing, research laboratories, electronics manufacturing, and hospitals where hygiene and contamination control are essential.

Q4. What is a PUF Panel door?

A.A PUF Panel door is a type of door made with Polyurethane Foam (PUF) insulation, offering airtight sealing, hygiene, and thermal efficiency—ideal for pharmaceuticals, food processing, and healthcare facilities. For detailed information, you can read our comprehensive blog on PUF Panel Door.

Q5. What features make PUF panel clean room doors superior?

A.PUF panel-based clean room doors offer airtight sealing, thermal and acoustic insulation, antibacterial surfaces, durability, and customizable finishes. These features make them a preferred choice across industries that demand precision and safety.

Conclusion

In industries where precision, hygiene, and safety are critical, choosing the right clean room doors can make all the difference. PUF panel-based solutions stand out as the ultimate choice, offering unmatched hygiene, superior insulation, and long-lasting durability. Unlike conventional options, these specialized cleanroom doors are designed to block contaminants, maintain temperature stability, and comply with international cleanroom standards—making them indispensable for pharmaceuticals, biotechnology, food processing, healthcare, and research environments.

Whether it’s a pharmaceutical clean room door for sterile manufacturing, a customized solution for a laboratory, or advanced clean room door design for a hospital or food facility, PUF panel technology ensures maximum efficiency and performance. The combination of airtight sealing, antibacterial properties, and low-maintenance features makes them a future-ready investment for any organization that values quality and compliance.

As a trusted clean room door manufacturer, MAKS Engineering has spent over 15 years perfecting the art of PUF panel solutions. Our doors are not only built to meet global standards but also tailored to meet the unique needs of every project. With expertise in design, quick installation, and proven project success, we are the partner of choice for businesses that want reliability and innovation in one package.

If you are looking for durable, hygienic, and efficient clean room doors, your search ends here. Contact MAKS Engineering today to discuss your requirements and discover how our custom-made cleanroom doors can elevate your facility to the next level of safety and performance. For more information about PUF Panels and doors and structures related to it, go to our Homepage.