PUF Panel Door

PUF Panel Door

In today’s fast-paced industrial and commercial sectors, the demand for energy-efficient, durable, and hygienic doors is higher than ever. This is where the PUF Panel Door has emerged as a game-changer. Designed with a high-quality polyurethane foam (PUF) core sandwiched between protective layers, PUF Doors offer superior thermal insulation, unmatched durability, and cost-effectiveness compared to traditional wooden or metal doors.

Whether it’s a cold storage facility, a pharmaceutical plant, a food processing unit, or even modular buildings, industries are rapidly shifting towards PUF Insulated Door solutions. The reason is simple—these doors not only help maintain temperature control and hygiene standards but also significantly reduce energy consumption, making them the preferred choice across multiple sectors.

At MAKS Engineering Co., we take pride in being among the top PUF Doors Manufacturers in India. With years of expertise, advanced technology, and a commitment to quality, we manufacture and supply premium-grade PUF Panel Doors tailored to meet diverse industrial requirements. What sets us apart is our ability to deliver solutions that strike the perfect balance between performance, durability, and affordability. We also ensure that the PUF Panel Door Price remains competitive, making our products accessible without compromising on quality.

By combining cutting-edge manufacturing techniques with a customer-first approach, MAKS Engineering Co. has established itself as a trusted partner for businesses looking for reliable PUF Panel Doors that meet international standards.

What is a PUF Panel Door?

A PUF Panel Door is a modern innovation in door technology, designed to meet the increasing demand for energy-efficient, durable, and low-maintenance solutions. The term PUF stands for Polyurethane Foam, a high-performance insulation material known for its exceptional thermal resistance and strength. When used in PUF Doors, this foam acts as a powerful insulating core that ensures long-lasting performance and superior energy savings.

PUF (Polyurethane Foam) Technology

Polyurethane Foam (PUF) is a rigid, closed-cell insulation material widely recognized for its excellent thermal insulation properties. In a PUF Insulated Door, this foam is sandwiched between outer sheets of galvanized steel, stainless steel, or other protective materials. The result is a lightweight yet highly robust door that prevents heat transfer, minimizes energy loss, and withstands harsh environmental conditions.

Structure of a PUF Panel Door

A typical PUF Panel Door is made up of three key layers:

Outer Sheet

Constructed from steel, aluminium, or stainless steel to provide strength, durability, and resistance to corrosion.

Insulated PUF Core

The heart of the door, filled with high-density polyurethane foam that delivers excellent insulation and reduces electricity costs.

Protective Finish

A smooth, hygienic coating that makes the surface resistant to moisture, bacteria, and wear, ensuring long service life with minimal maintenance.

Difference Between PUF Panel Doors and Conventional Doors

Unlike conventional wooden or metal doors that are heavy, prone to warping, and poor at insulation, PUF Doors are specifically engineered to combine lightweight design with maximum thermal efficiency. Traditional doors often struggle with durability in humid or temperature-sensitive environments, while a PUF Insulated Door maintains structural integrity and delivers consistent performance even under extreme conditions.

Additionally, when considering the PUF Panel Door Price, it is highly cost-effective in the long run. Businesses save significantly on electricity bills and maintenance costs, making these doors a smarter investment compared to traditional alternatives. This is why leading PUF Doors Manufacturers like MAKS Engineering Co. are witnessing a surge in demand across industries such as cold storage, pharmaceuticals, food processing, and modular construction.

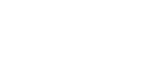

Key Features of PUF Panel Doors

When investing in industrial or commercial infrastructure, choosing the right type of door is crucial for efficiency, safety, and cost savings. A PUF Panel Door stands out as a modern solution because of its advanced design and unique benefits that go far beyond what conventional doors can offer. Below are the key features that make PUF Doors the preferred choice across multiple industries.

1. Superior Thermal Insulation for Energy Savings

One of the biggest advantages of a PUF Insulated Door is its ability to minimize heat transfer. The high-density polyurethane foam core ensures excellent thermal insulation, making these doors perfect for cold storage units, food processing plants, and pharmaceutical facilities. By maintaining consistent indoor temperatures, they help businesses cut down on electricity bills and ensure long-term energy savings.

2. Exceptional Durability & Strength

Unlike wooden doors that warp or metal doors that corrode, a PUF Panel Door is designed for long-lasting performance. It is resistant to corrosion, moisture, and wear, even in challenging environments. This durability translates into lower maintenance costs and better returns on investment compared to other options available at a similar PUF Panel Door Price.

3. Lightweight Yet Sturdy Design

Despite their robust build, PUF Doors are surprisingly lightweight. This makes them easier to install, operate, and maintain without compromising strength. Their structural stability ensures they can withstand frequent use in high-traffic areas, making them an ideal choice for warehouses, commercial spaces, and modular buildings.

4. Hygienic & Easy to Clean

A PUF Insulated Door comes with a protective outer layer that is smooth, non-porous, and resistant to bacterial growth. This feature makes it highly suitable for industries like pharmaceuticals, hospitals, and food processing units, where hygiene is non-negotiable. Cleaning and maintenance are simple, which adds to their efficiency in regulated environments.

5. Customizable Sizes and Finishes

Every project has different requirements, and leading PUF Doors Manufacturers like MAKS Engineering Co. specialize in offering fully customizable solutions. Whether you need specific dimensions, finishes, or door fittings, a PUF Panel Door can be tailored to match your exact needs. This flexibility ensures maximum efficiency and a seamless fit for every application.

With a combination of insulation, strength, hygiene, and customization, PUF Panel Doors deliver unmatched value for industries looking to upgrade their infrastructure. Add to this the competitive PUF Panel Door Price, and it’s easy to see why they are considered the smart choice for modern businesses.

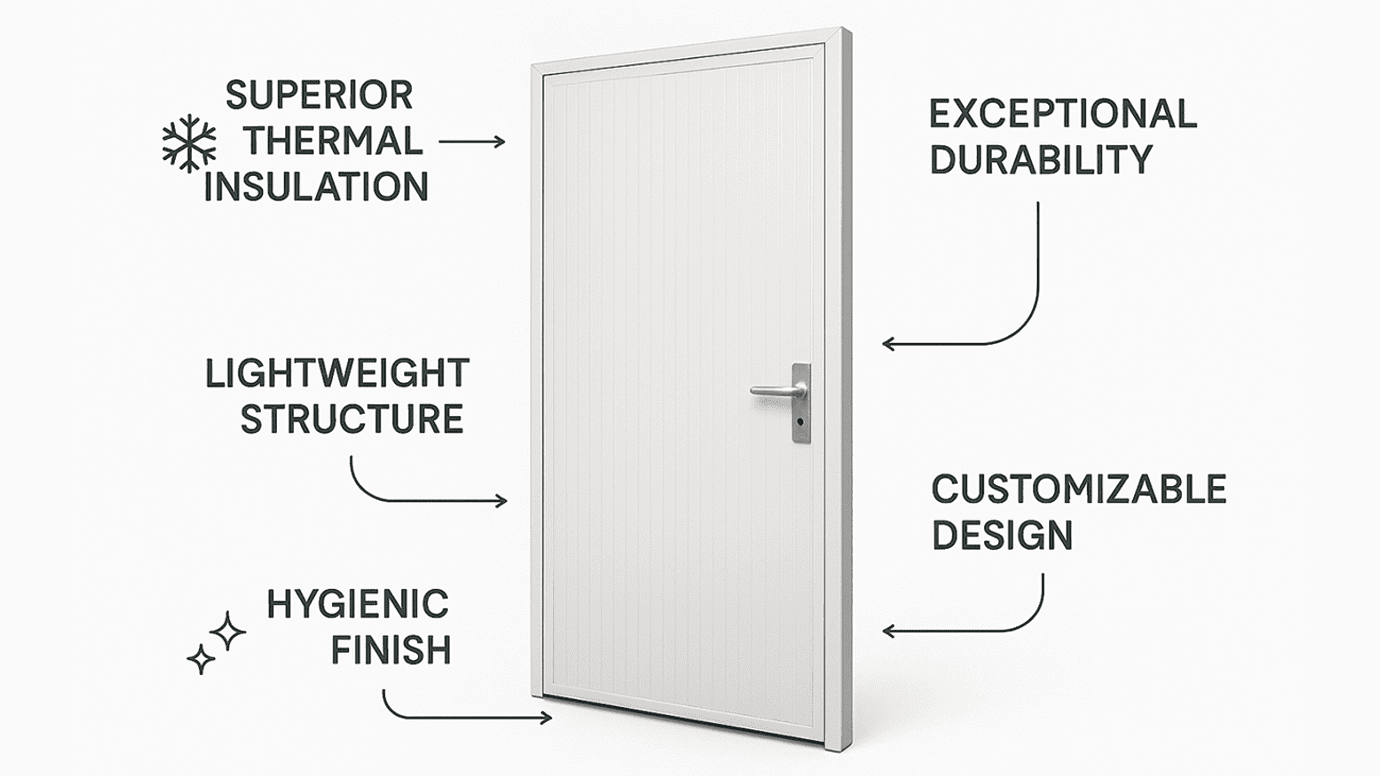

Applications of PUF Panel Doors

The versatility of a PUF Panel Door makes it an indispensable choice across a wide range of industries. Engineered with advanced polyurethane foam insulation, PUF Doors are not only durable but also deliver unmatched thermal efficiency and hygiene. This has made them the go-to solution for businesses seeking reliability, cost savings, and long-term performance. Let’s explore the most common applications of a PUF Insulated Door.

Cold Storage Facilities

Maintaining a consistent temperature is critical in cold storage, and this is where a PUF Panel Door plays a vital role. Its superior insulation helps retain cooling efficiency, ensuring perishable goods remain fresh while drastically reducing energy consumption. For businesses, this means lower electricity bills and maximum ROI, especially when considering the overall PUF Panel Door Price compared to traditional options.

Food Processing Units

In the food industry, hygiene and contamination control are top priorities. A PUF Insulated Door comes with a smooth, non-porous finish that prevents bacterial growth and is easy to clean. This makes PUF Doors ideal for food processing plants, packaging units, and storage facilities where strict hygiene standards are enforced.

Durability and Corrosion Resistance

Unlike ordinary industrial doors, premium cold room doors are designed for long-term durability in refrigerated and humid environments. They are constructed with corrosion-resistant materials that can withstand constant temperature variations, frequent use, and exposure to moisture. Reliable cold storage door manufacturers focus on delivering products that maintain their structural integrity for years.

Pharmaceutical & Healthcare Facilities

Hospitals, labs, and pharmaceutical manufacturing plants require controlled environments to maintain safety and product quality. A PUF Panel Door ensures air-tight sealing, temperature stability, and resistance to microbial growth. Leading PUF Doors Manufacturers recommend these solutions for cleanrooms, medicine storage, and healthcare infrastructure where precision and hygiene cannot be compromised.

Commercial Buildings & Modular Structures

From offices to modular homes, a PUF Panel Door provides a modern, energy-efficient alternative to conventional doors. Its lightweight yet sturdy design makes it easy to install and maintain, while customizable finishes allow architects and builders to align functionality with aesthetics. The competitive PUF Panel Door Price further enhances its appeal for commercial and modular construction projects.

Industrial Warehouses

Warehouses demand robust doors that can withstand heavy use, temperature variations, and external wear. PUF Doors provide the perfect balance of durability and insulation, ensuring products remain safe while lowering operational costs. Their strength and longevity make them an ideal investment for large-scale industrial facilities.

With applications spanning cold storage, pharmaceuticals, food industries, commercial projects, and warehouses, it’s clear that the PUF Panel Door is not just a door but a strategic solution that enhances efficiency, hygiene, and energy savings across sectors. No wonder businesses across India trust PUF Doors Manufacturers like MAKS Engineering Co. for reliable and customized solutions.

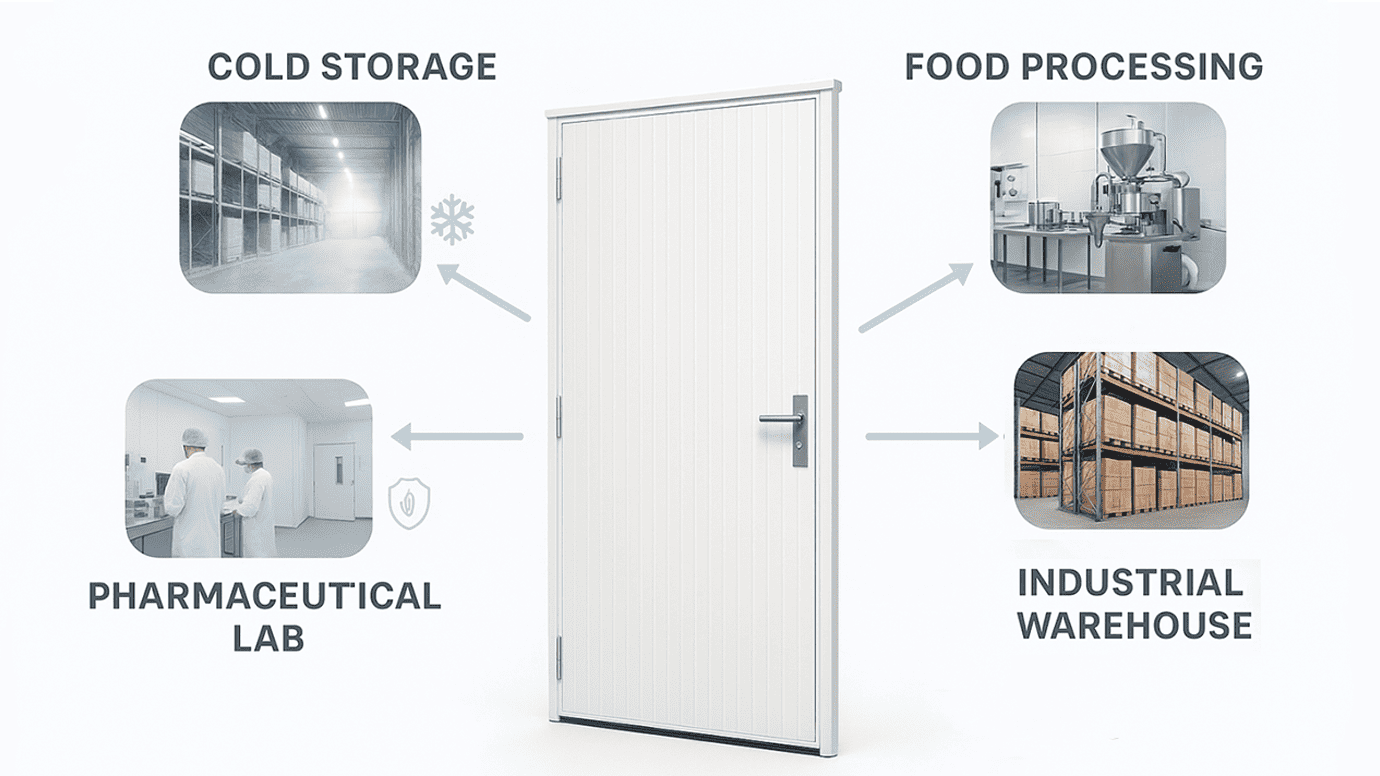

Advantages of Choosing PUF Panel Doors from MAKS Engineering Co.

When it comes to selecting a PUF Panel Door, businesses often look for more than just durability and insulation—they want reliability, customization, and long-term value. At MAKS Engineering Co., we combine years of expertise with advanced manufacturing capabilities to deliver world-class PUF Doors that meet the needs of diverse industries. Here’s why partnering with us ensures you get the best solutions in the market:

In-House Manufacturing Excellence

As one of the leading PUF Doors Manufacturers in India, we maintain complete control over the production process. From raw material selection to final assembly, our PUF Insulated Door units are manufactured in-house using state-of-the-art machinery. This ensures consistent quality, faster delivery timelines, and competitive PUF Panel Door Price without compromising on standards.

Custom-Built Doors to Meet Client Requirements

No two projects are the same, and we recognize the importance of customization. Whether it’s specific dimensions, finishes, or specialized fittings, we design and deliver tailor-made PUF Insulated Door solutions that perfectly align with client needs. This flexibility is one of the main reasons our clients prefer us over other PUF Doors Manufacturers in the market.

End-to-End Project Support

We don’t just manufacture doors—we provide complete solutions. From design and consultation to production, delivery, and on-site installation, our team ensures a smooth, hassle-free process. Choosing our PUF Doors means choosing a partner who will support you at every stage of the project lifecycle.

At MAKS Engineering Co., we believe that a PUF Panel Door is more than just a product—it’s a long-term investment in performance, efficiency, and sustainability. With our competitive PUF Panel Door Price, certified quality, and unmatched customer support, we continue to set benchmarks in the industry as one of India’s most trusted PUF Doors Manufacturers.

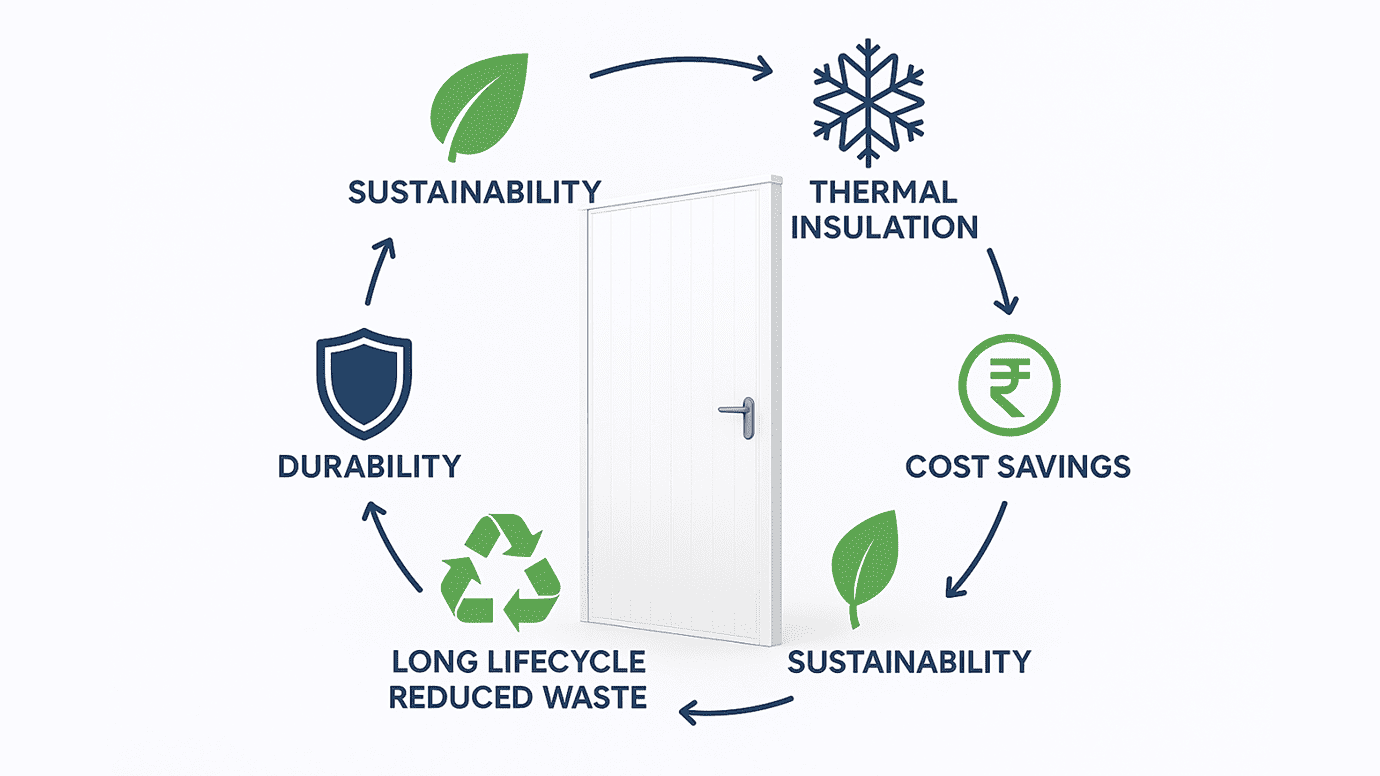

Why PUF Panel Doors are the Future of Energy-Efficient Infrastructure

The construction industry is rapidly evolving, with a strong focus on sustainability, energy efficiency, and eco-friendly practices. In this shift toward greener infrastructure, the PUF Panel Door has emerged as a smart, future-ready solution. Designed with advanced insulation technology and durable materials, PUF Doors are proving to be indispensable in modern industrial, commercial, and residential applications.

Role in Sustainability & Eco-Friendly Construction

A PUF Insulated Door is not just a barrier—it’s an active contributor to sustainable building practices. By reducing energy loss, lowering carbon footprints, and ensuring longer service life, these doors align perfectly with the goals of eco-friendly construction. Unlike traditional wooden or metal doors, a PUF Panel Door requires less maintenance and has a significantly longer lifecycle, which means fewer replacements and less environmental waste.

Contribution to Energy Cost Reduction

One of the greatest advantages of choosing PUF Doors is the remarkable impact they have on reducing energy bills. Thanks to the high-density polyurethane foam core, these doors provide exceptional thermal insulation, helping maintain consistent temperatures in cold storage, pharmaceuticals, food processing units, and modular buildings. Businesses investing in PUF Insulated Doors not only save money on daily electricity consumption but also enjoy long-term financial benefits compared to traditional options, even when factoring in the PUF Panel Door Price.

Ideal for Modern Prefabricated Structures

As prefabricated and modular construction continues to grow in popularity, the demand for versatile and efficient door solutions has increased. A PUF Panel Door is lightweight yet strong, making it easy to integrate into modular designs without adding unnecessary load. With customizable finishes and sizes, they seamlessly blend with modern architectural aesthetics while delivering unmatched insulation performance. This is why leading PUF Doors Manufacturers, including MAKS Engineering Co., recommend them as the ideal choice for future-ready infrastructure.

By combining sustainability, cost-effectiveness, and adaptability, PUF Panel Doors are setting new benchmarks for the future of construction. They are more than just doors—they are a strategic investment in energy-efficient infrastructure that benefits both businesses and the environment.

Maintenance & Longevity of PUF Panel Doors

One of the strongest reasons businesses choose a PUF Panel Door is its impressive longevity and low maintenance requirements. Unlike conventional wooden or metal doors that may warp, rust, or lose efficiency over time, PUF Doors are built to withstand years of heavy use while maintaining their structural integrity and insulation efficiency.

How Long Do PUF Doors Last?

A high-quality PUF Insulated Door can easily last for 15–20 years or more, depending on usage and environmental conditions. Thanks to the high-density polyurethane foam core and protective outer sheets, a PUF Panel Door resists wear and tear far better than traditional options. This durability makes it a cost-effective investment, especially considering the competitive PUF Panel Door Price offered by trusted PUF Doors Manufacturers like MAKS Engineering Co.

Simple Cleaning & Maintenance Tips

Maintaining a PUF Insulated Door is hassle-free. Regular cleaning with mild detergent and a soft cloth is sufficient to keep the surface hygienic and stain-free. Since the outer finish is smooth and non-porous, dirt and bacteria do not accumulate easily, making these doors perfect for environments where hygiene is critical, such as pharmaceuticals and food processing units. Routine inspections to check hinges, locks, and seals can further extend the life of PUF Doors.

Resistance to Extreme Weather Conditions

Whether exposed to humidity, high temperatures, or extreme cold, a PUF Panel Door maintains its strength and performance. The insulated core prevents expansion or contraction due to weather fluctuations, while the protective finish ensures resistance against corrosion, moisture, and harsh environmental factors. This makes PUF Doors ideal not only for indoor facilities but also for industrial warehouses and modular structures exposed to challenging conditions.

With their long lifespan, minimal maintenance needs, and ability to withstand extreme climates, PUF Panel Doors provide unmatched value for money. By investing in solutions from reliable PUF Doors Manufacturers, businesses can be confident that they are choosing doors that combine durability, hygiene, and cost-efficiency—all at a competitive PUF Panel Door Price.

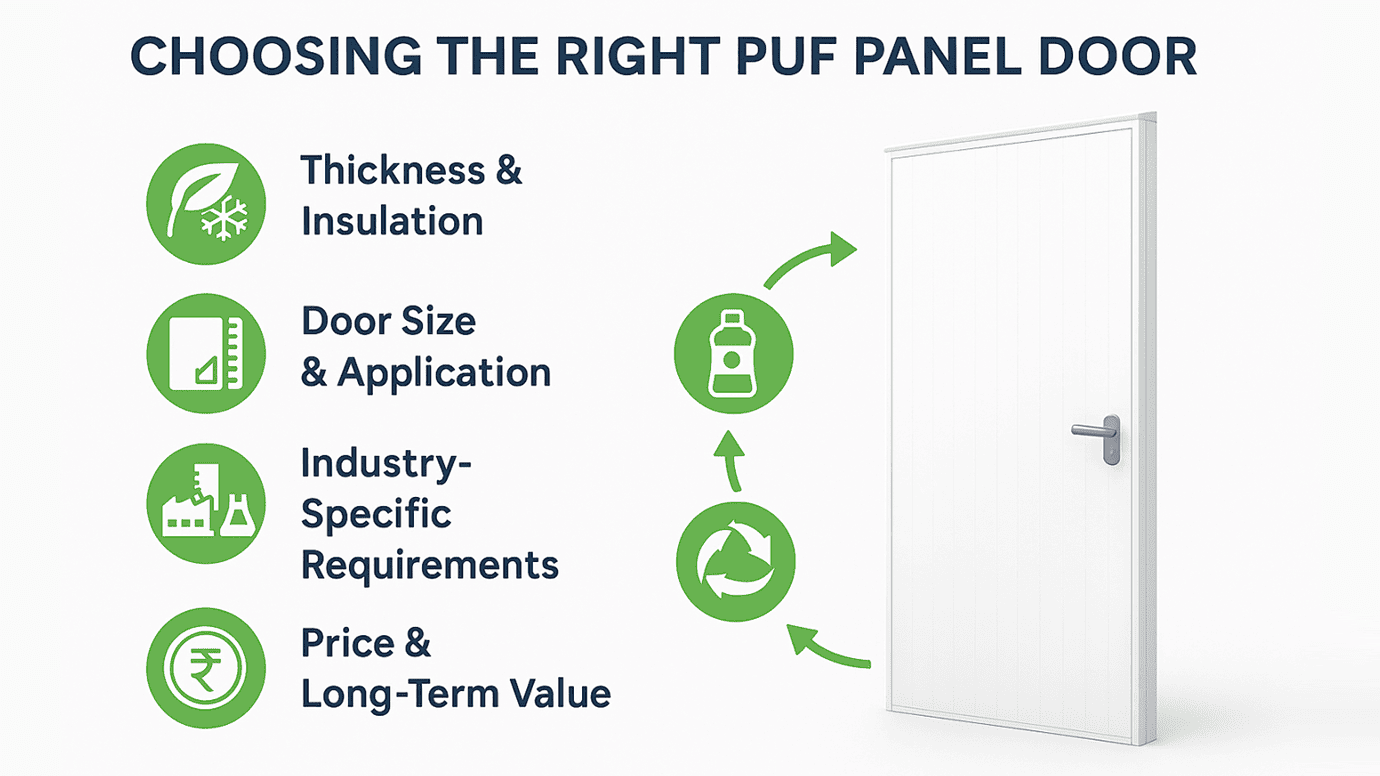

How to Choose the Right PUF Panel Door

Selecting the perfect PUF Panel Door for your facility is more than just a matter of design—it’s about finding the right balance between insulation, durability, size, and cost-effectiveness. Since industries like pharmaceuticals, cold storage, food processing, and modular construction all have different requirements, choosing the right solution is critical for performance and efficiency.

Consider the Thickness & Insulation Level

The insulation efficiency of a PUF Insulated Door largely depends on its thickness and the density of the polyurethane foam core. For cold storage facilities, thicker doors with higher insulation levels are recommended to maintain consistent temperature and reduce energy consumption. On the other hand, commercial and modular structures may require moderate insulation where aesthetics and functionality go hand in hand.

Evaluate the Door Size & Application

Before finalizing a PUF Panel Door, it’s essential to assess the size requirements based on your facility layout. Large industrial warehouses may require oversized PUF Doors, while pharmaceutical labs or modular cabins may need compact designs. The versatility of these doors makes them suitable for nearly any application, but accurate measurements are key to seamless installation.

Match to Industry-Specific Requirements

Each sector has unique standards and compliance needs. For example:

- Food processing units demand hygienic, easy-to-clean finishes.

- Pharmaceutical plants require airtight sealing for controlled environments.

- Warehouses prioritize strength and durability.

- Modular structures often need lightweight designs that are easy to install.

Choosing the right PUF Panel Door means aligning features with industry requirements to maximize efficiency and compliance.

Factor in the PUF Panel Door Price

While upfront cost is important, businesses should always consider the long-term savings that come from reduced energy bills and lower maintenance costs. A slightly higher price from reputed PUF Doors Manufacturers often delivers far greater value than cheaper, low-quality alternatives.

By carefully evaluating thickness, insulation, size, application, and cost, businesses can make an informed choice and invest in a PUF Panel Door that ensures durability, efficiency, and long-term savings. With professional guidance from MAKS Engineering Co., you can be confident of selecting the perfect solution tailored to your industry.

FAQs:

Q1. What is a PUF Panel Door and how is it different from traditional doors?

A. A PUF Panel Door is built with a polyurethane foam (PUF) core sandwiched between protective sheets, offering excellent insulation and durability. Unlike wooden or metal doors, PUF Doors are lightweight, resistant to corrosion, and deliver superior energy efficiency.

Q2. What industries commonly use PUF Insulated Doors?

A. PUF Insulated Doors are widely used in cold storage facilities, food processing units, pharmaceutical plants, modular structures, and industrial warehouses. These industries prefer them because they ensure temperature control, hygiene, and long-term durability.

Q3. How long does a PUF Panel Door last?

A. With proper maintenance, a PUF Panel Door can last 15–20 years or more. Their resistance to weather, corrosion, and wear makes them a more reliable investment compared to traditional options.

Q4. What is the typical PUF Panel Door Price?

A. The PUF Panel Door Price depends on factors like door size, thickness, insulation level, and customization requirements. While the initial price may be slightly higher than conventional doors, the long-term energy savings and durability make it cost-effective.

Q5. What makes PUF Panel Doors suitable for Cold Rooms?

A. A PUF Panel Door helps maintain precise temperature control in cold rooms by minimizing heat transfer, reducing energy costs, and offering long-lasting durability even under continuous use. For more information, you can read our dedicated blog on Cold Room Doors.

Q6. Are PUF Doors easy to maintain?

A. Yes, PUF Doors require minimal maintenance. A simple cleaning with mild detergent is enough to keep them hygienic. Regular checks of hinges and seals ensure smooth operation and extend their lifespan.

Q7. Are PUF Panel Doors suitable for extreme weather conditions?

A. Yes, a PUF Insulated Door performs well in all weather conditions. It resists moisture, high humidity, extreme cold, and heat while maintaining its structural strength and insulation properties.

Q8. Why are PUF Panel Doors ideal for Operation Theatres?

A. A PUF Insulated Door is perfect for operation theatres because it provides airtight sealing, excellent thermal insulation, and a hygienic, smooth surface that resists bacterial growth, ensuring a sterile environment. For detailed information, read our comprehensive blog on Operation Theatre Doors.

Conclusion

In today’s competitive and energy-conscious world, choosing the right door solution can make a significant difference in both performance and cost savings. A PUF Panel Door is not just a structural component—it is a strategic investment that delivers superior thermal insulation, durability, hygiene, and long-term efficiency. From cold storage facilities and food processing units to pharmaceutical plants, warehouses, and modular structures, the applications of PUF Doors are vast and growing rapidly.

The combination of sustainability, strength, and cost-effectiveness makes the PUF Insulated Door the preferred choice for modern infrastructure. Businesses benefit not only from reduced energy bills but also from long-lasting reliability and minimal maintenance needs. When you factor in the competitive PUF Panel Door Price, it becomes clear that these doors offer far greater value compared to traditional alternatives.

At MAKS Engineering Co., we take pride in being one of the most trusted PUF Doors Manufacturers in India. With in-house manufacturing excellence, ISO-certified quality standards, and a proven track record of delivering custom-built solutions, we ensure that every client receives a door that meets their exact requirements. From design and consultation to manufacturing and installation, our team provides end-to-end support for every project.

If you’re looking for durable, hygienic, and energy-efficient solutions, investing in a PUF Panel Door from MAKS Engineering Co. is the smart choice. Contact us today to discover how our high-performance PUF Doors can transform your facility with unmatched efficiency, reliability, and value.

For more information regarding PUF Panels and structures related to it, you can go to our Homepage.