PUF Panel Prefabricated Labour Camps

PUF Panel Prefabricated Labour Camps

In recent years, the construction industry has witnessed a significant surge in the demand for prefabricated construction. This trend is not just a passing wave but a substantial shift towards more sustainable, efficient, and cost-effective building methods. Among the various applications of prefabrication, prefabricated labour camps have emerged as a cornerstone in modern construction projects, especially in regions experiencing rapid industrial growth and those with temporary housing needs for large workforces.

Prefabricated labour camps are designed to offer quick, efficient, and flexible accommodation solutions. They are crucial in sectors such as mining, oil and gas, construction, and large-scale industrial activities, where there is a need to house workers comfortably and safely near their work sites. These prefabricated labour camps are not only a testament to the practicality and efficiency of using modular construction methods but also highlight the industry’s shift towards more humane and dignified living conditions for workers.

At the heart of these innovative construction solutions are PUF (Polyurethane Foam) panels, which have revolutionized how these prefabricated labour camps are built. PUF panels are lauded for their excellent thermal insulation properties, which make them ideal for both hot and cold climates. Moreover, their lightweight nature simplifies and speeds up the construction process, allowing for labour camps to be assembled, disassembled, and relocated with minimal environmental and financial impact. The use of PUF panels in prefabricated labour camps not only enhances the energy efficiency of these structures but also contributes significantly to their sustainability and durability, aligning with global environmental goals and modern construction practices.

The integration of PUF panels in prefabricated labour camps exemplifies how cutting-edge materials can meet critical needs while promoting environmental stewardship and efficiency. As the world leans more towards sustainable development, the role of prefabricated labour camps equipped with advanced materials like PUF panels becomes increasingly pivotal, marking a progressive step in the evolution of building practices that cater to both human and environmental well-being.

What are Prefabricated Labour Camps?

Prefabricated labour camps are specialized housing solutions designed to provide temporary to semi-permanent accommodations for workers, typically at or near construction and industrial sites. These structures are manufactured in a factory setting and then transported to the designated location where they are quickly assembled, providing a fast and efficient setup of essential facilities. This method significantly contrasts with traditional construction techniques, which often require more time and resources.

The primary purpose of prefabricated labour camps is to offer a safe, comfortable, and efficient living environment for workers, who might otherwise have to travel long distances or live in substandard conditions. These prefabricated labour camps ensure that workers have access to all necessary amenities, including sleeping quarters, kitchens, bathrooms, and recreational areas, all within a close distance to their workplace.

Types of Prefabricated Labour Camps

Prefabricated labour camps come in various types, ranging from temporary structures, which are ideal for short-term projects, to semi-permanent installations, which can last for several years and are suited for longer construction projects or in areas where permanent buildings are not feasible. Temporary camps are often used in disaster relief operations or seasonal work environments, whereas semi-permanent camps might be found in mining or oil extraction industries where operations last longer but do not justify permanent infrastructure.

Choosing prefabricated solutions for labour accommodations offers numerous benefits:

- Speed of Construction: These prefabricated labour camps can be deployed rapidly, which is crucial for projects with tight deadlines or in emergency situations.

- Cost-Effectiveness: Prefabrication reduces the overall cost of construction and site management due to economies of scale in the factory and reduced on-site labor and waste.

- Flexibility: Modules can be added, removed, or reconfigured as project needs change, providing adaptability to varying workforce sizes.

- Quality Control: Components of the camps are built in controlled factory environments, which improves the quality and consistency of the structures.

- Sustainability: These camps are often designed with sustainability in mind, featuring materials and systems that minimize energy consumption and reduce waste.

Overall, prefabricated labour camps represent a smart choice for businesses looking to manage the logistical challenges of housing employees in remote or temporary work sites effectively. They not only provide essential needs in a functional manner but also enhance the well-being and productivity of workers by offering a stable and comfortable living environment.

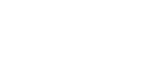

Understanding PUF Panels

In the world of prefabricated labour camps, PUF (Polyurethane Foam) panels stand out as a revolutionary building material that brings unparalleled benefits to modern construction methods. These panels are essential components in creating efficient, safe, and comfortable housing solutions for workers in various industries.

PUF panels consist of polyurethane foam sandwiched between two structural facings, typically made of steel or aluminium. This foam is a product of a chemical reaction that occurs when a polyol and an isocyanate, two key polyurethane components, are mixed. The mixture expands to form a rigid foam that is both lightweight and extremely insulating. The manufacturing process involves injecting the foam between the panels in a controlled factory environment, ensuring consistent quality and performance.

The properties of PUF panels make them particularly suited for prefabricated labour camps due to the following advantages:

- Superior Insulation: PUF panels provide excellent thermal insulation, a critical factor in maintaining comfortable living conditions in varying climates. This insulation capability ensures that energy costs are kept low, as less heating and cooling are required to maintain a stable internal temperature.

- Lightweight Yet Strong: Despite their lightweight nature, PUF panels are incredibly durable and can support significant structural loads, making them easy to transport and assemble while still ensuring robust construction.

- Durability and Longevity: PUF panels are designed to withstand harsh environmental conditions, including extreme temperatures and heavy impacts. Their longevity is enhanced by their resistance to decay and pests, ensuring that they remain in good condition for years without requiring extensive maintenance.

- Fire and Moisture Resistance: Safety in prefabricated labour camps is paramount, and PUF panels contribute positively in this area. They are manufactured to be fire resistant, which helps in preventing the spread of fire, should one occur. Additionally, the panels have excellent moisture resistance, preventing mold and water damage, which are common issues in less durable materials.

- Sound Insulation Qualities: The dense foam core of PUF panels also serves as an effective sound barrier, reducing noise from outside and between different sections of the prefabricated labour camps. This quality is especially beneficial in promoting a quiet and restful environment for workers.

The integration of PUF panels in the construction of prefabricated labour camps not only enhances the living conditions but also boosts the overall efficiency of assembly and longevity of the structures.

The Design Flexibility of PUF Panels

One of the standout features of PUF panels in the construction of prefabricated labour camps is their incredible design flexibility. This versatility enables architects and engineers to tailor designs specifically to the needs of each project, ranging from straightforward layouts for small-scale sites to more complex configurations for large-scale operations. The adaptability of PUF panels not only facilitates customization in building design but also significantly enhances the functionality and efficiency of the structures they help create.

Customization Options Available with PUF Panels

PUF panels offer extensive customization options which make them particularly appealing for use in prefabricated labour camps. These panels can be manufactured in various sizes and thicknesses, accommodating different insulation requirements and structural loads. Furthermore, the outer layers of the panels can be finished with a variety of materials, colors, and textures, allowing for aesthetic integration into local environments or adherence to corporate branding.

Architectural Versatility: From Simple Layouts to Complex Designs

The lightweight and easy-to-modify nature of PUF panels allows for architectural innovation in designing prefabricated labour camps. Whether the requirement is for simple, single-story buildings or more sophisticated multi-story structures, PUF panels can be utilized effectively. Their ease of assembly and disassembly also supports modular designs, where additional units can be seamlessly added or removed as the workforce and project demands evolve over time. This flexibility is crucial in responding to the changing needs of a project without significant disruptions or additional costs.

Integration with Other Materials and Systems for Enhanced Functionality

PUF panels are designed to work harmoniously with other building materials and systems, enhancing the overall functionality of prefabricated labour camps. For instance, they can be easily integrated with electrical and plumbing systems, ensuring that these essential services are embedded during the initial construction phase, which reduces installation times and potential for errors. Additionally, PUF panels can be combined with traditional building materials like wood, metal, and concrete, providing structural diversity and resilience while still benefiting from the insulation and lightweight properties of the panels.

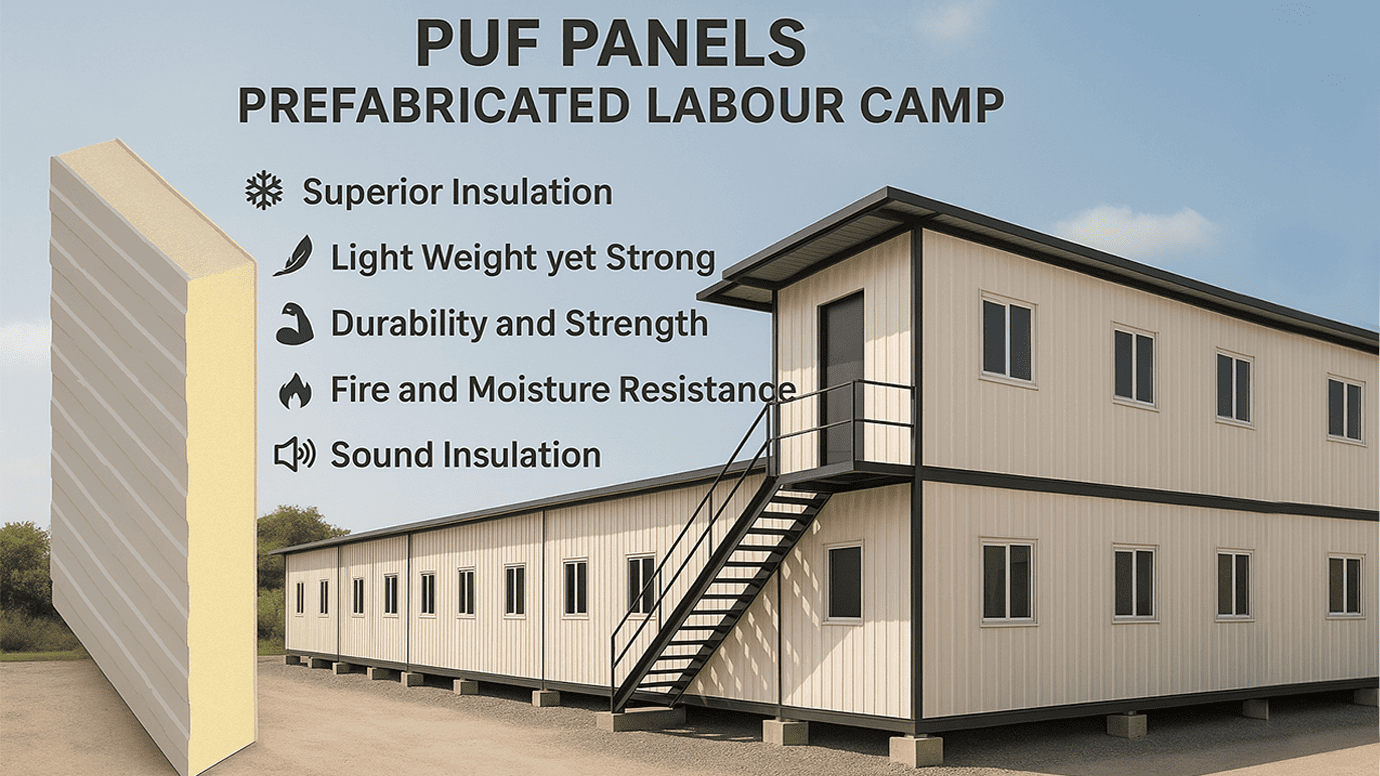

Moreover, the integration capabilities extend to renewable energy systems such as solar panels. The roofs of prefabricated labour camps made from PUF panels are often ideal for supporting solar installations, which can provide a sustainable and cost-effective power supply to the camps. This synergy not only enhances the energy efficiency of the camps but also promotes a greener construction approach.

Overall, the design flexibility of PUF panels significantly contributes to the practical and aesthetic success of prefabricated labour camps. By allowing for easy customization, architectural versatility, and seamless integration with other materials and systems, PUF panels help create functional, comfortable, and sustainable accommodations tailored to the unique needs of each project.

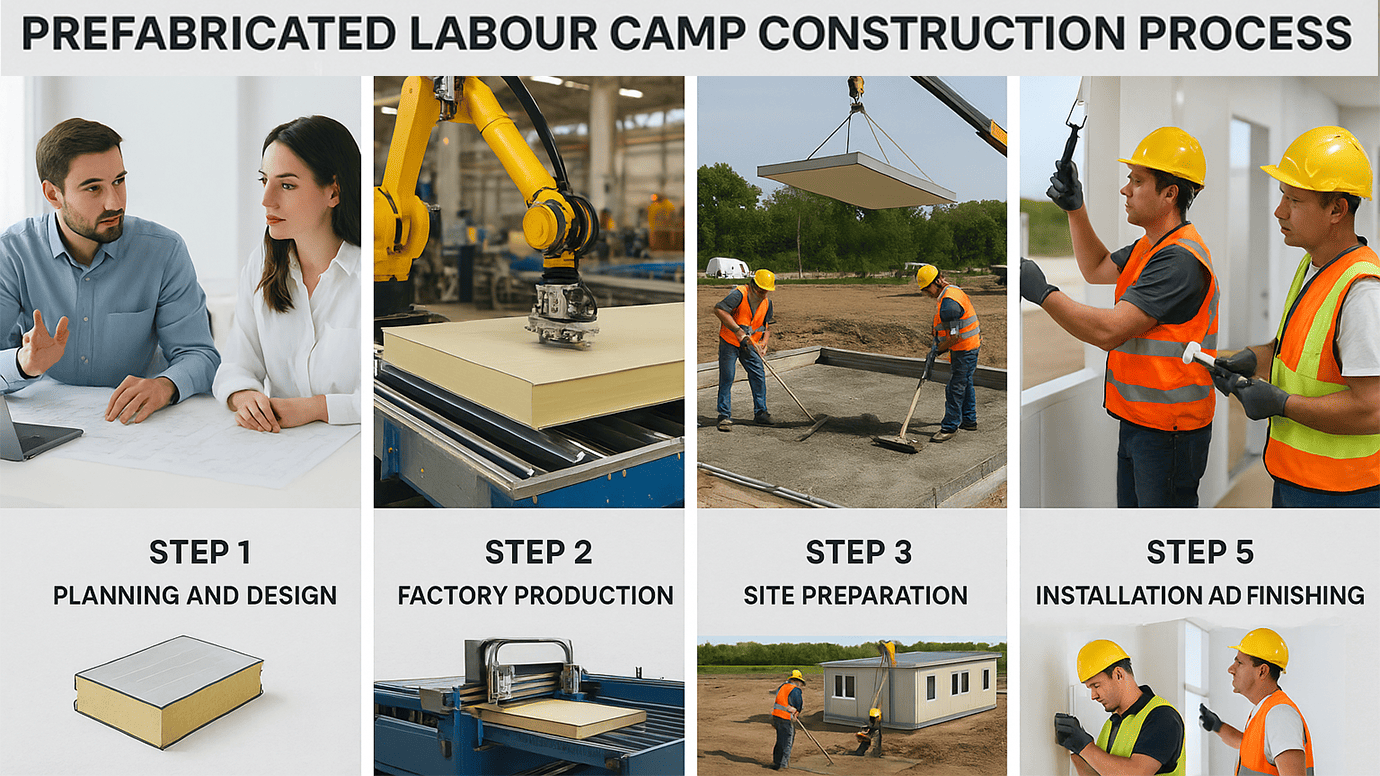

The Construction Process of Prefabricated Labour Camps Using PUF Panels

The construction of prefabricated labour camps using PUF panels is a streamlined process that showcases the efficiency and effectiveness of modern building techniques. This method not only accelerates the building timeline but also ensures high-quality outcomes. Here, we outline the detailed phases involved in constructing these prefabricated labour camps and compare the timeframe with traditional construction methods to highlight the advantages of using PUF panels.

Planning and Design

The first phase in the construction of prefabricated labour camps involves meticulous planning and design. This stage is crucial as it addresses all the requirements of the camp, including the number of occupants, necessary facilities, environmental considerations, and compliance with local building codes. Utilizing PUF panels allows for flexible design options, enabling architects to create both functional and comfortable living spaces that can be easily adapted as needs change.

Production of PUF Panels

Once the design is finalized, the production of PUF panels begins in a controlled factory environment. This phase benefits from automated processes that ensure precision and consistency in the panels' quality. The polyurethane foam is injected between two protective layers, typically made of metal, creating a lightweight yet sturdy panel that offers excellent insulation properties. The factory setting also allows for the customization of panel sizes and finishes according to the project’s specific requirements.

Site Preparation and Foundation Setting

Concurrently with panel production, the construction site is prepared. This involves clearing the land, setting up access roads, and preparing the foundation. For prefabricated labour camps, foundations can range from simple concrete slabs to more complex structures, depending on the terrain and the duration the camp will be in use. Proper site preparation ensures that the assembly process will run smoothly and that the structures will be stable and secure.

Erection and Assembly of Panels

The erection and assembly phase is where the speed and simplicity of using PUF panels become evident. Once delivered to the site, the panels are quickly assembled into the predefined layouts. This process is significantly faster than traditional construction methods, as the panels are designed to interlock or attach with minimal effort, reducing the need for skilled labour on-site and accelerating the overall construction timeline.

Installation of Utilities and Finishing Works

With the shell of the camp in place, the next step is the installation of utilities, including electrical wiring, plumbing, and HVAC systems. PUF panels come pre-designed for easy integration of these systems, which speeds up this phase. Finishing works, such as internal fixtures, painting, and external cladding, are then completed to make the spaces liveable and visually appealing.

Comparison of Timeframes with Traditional Construction Methods

When compared to traditional construction methods, the use of PUF panels in prefabricated labour camps dramatically reduces the overall construction time. Traditional methods might take several months to over a year depending on the project scale, while prefabricated labour camps can be erected and made operational in a fraction of that time, often within weeks. This speed not only leads to cost savings on labour and site management but also means that projects can start their operations sooner, a critical advantage in many industrial applications.

In conclusion, the construction process of prefabricated labour camps using PUF panels exemplifies modern construction efficiency. From planning through to completion, each phase is optimized for speed, quality, and adaptability, highlighting why this method is increasingly chosen for worker accommodations in various sectors.

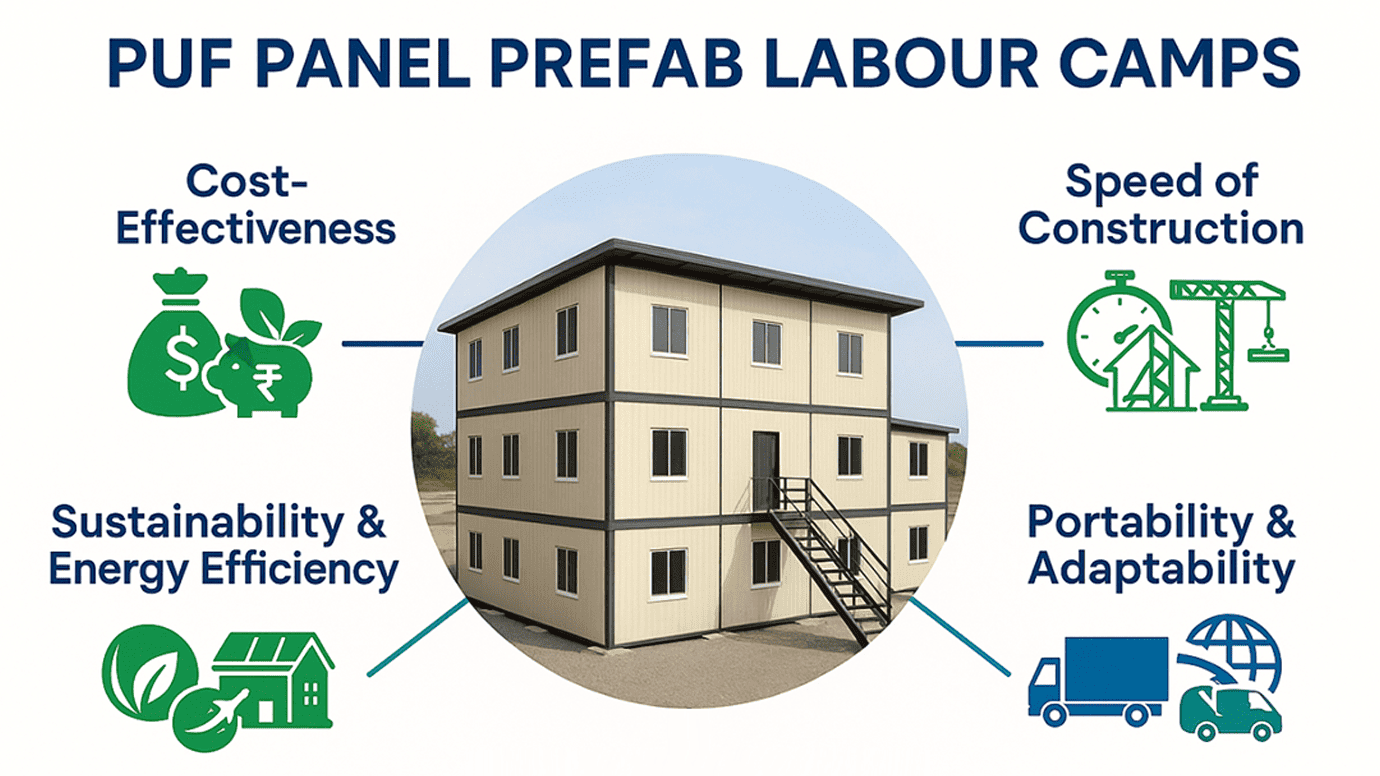

Advantages of PUF Panel Prefabricated Labour Camps

Prefabricated labour camps constructed with PUF panels present a multitude of advantages that make them superior to traditional construction methods. The utilization of PUF panels in prefabricated labour camps not only enhances the structural efficiency but also brings long-term economic and environmental benefits. Here, we explore the key advantages of these innovative materials in prefabricated labour camps.

Cost-Effectiveness Including Long-Term Savings

One of the most significant benefits of using PUF panels in prefabricated labour camps is their cost-effectiveness. The initial setup costs for prefabricated labour camps are often lower due to streamlined production and assembly processes, which require less labor and minimize waste. Additionally, the superior insulation properties of PUF panels significantly reduce the energy consumption required for heating and cooling the prefabricated labour camps, leading to considerable long-term savings. These cost reductions are a vital aspect of the financial appeal of prefabricated labour camps.

Speed of Construction

The construction speed of prefabricated labour camps using PUF panels is remarkably fast. Since the panels are pre-manufactured in a controlled environment, the assembly process at the actual site is greatly expedited. Prefabricated labour camps can be operational in a fraction of the time it takes to build traditional structures, making them ideal for projects that require rapid deployment, such as emergency housing or remote project sites.

Sustainability: Environmental Impact and Energy Efficiency

Prefabricated labour camps built with PUF panels are notably sustainable. The production of PUF panels for prefabricated labour camps results in minimal waste, and their lightweight nature reduces transportation emissions. Furthermore, the energy efficiency of PUF panels drastically lowers the energy demands of prefabricated labour camps, enhancing their overall sustainability. This reduced carbon footprint is crucial for companies committed to environmental responsibility in their construction projects.

Portability and Adaptability to Different Sites and Climates

The design of PUF panels lends exceptional portability and adaptability to prefabricated labour camps. These camps can be easily relocated, thanks to the lightweight and modular nature of PUF panels. Moreover, PUF panels are engineered to perform under diverse climatic conditions, ensuring that prefabricated labour camps remain comfortable and durable, whether in extreme cold, heat, or variable weather conditions. This versatility is essential for prefabricated labour camps that serve industries like mining, oil, and construction, where adaptability to site-specific conditions is required.

In essence, the use of PUF panels in prefabricated labour camps offers substantial advantages in terms of cost savings, rapid construction, sustainability, and adaptability. These benefits highlight why PUF panels are increasingly preferred in the construction of prefabricated labour camps, offering an effective solution to the traditional challenges of building durable, efficient, and environmentally friendly worker accommodations.

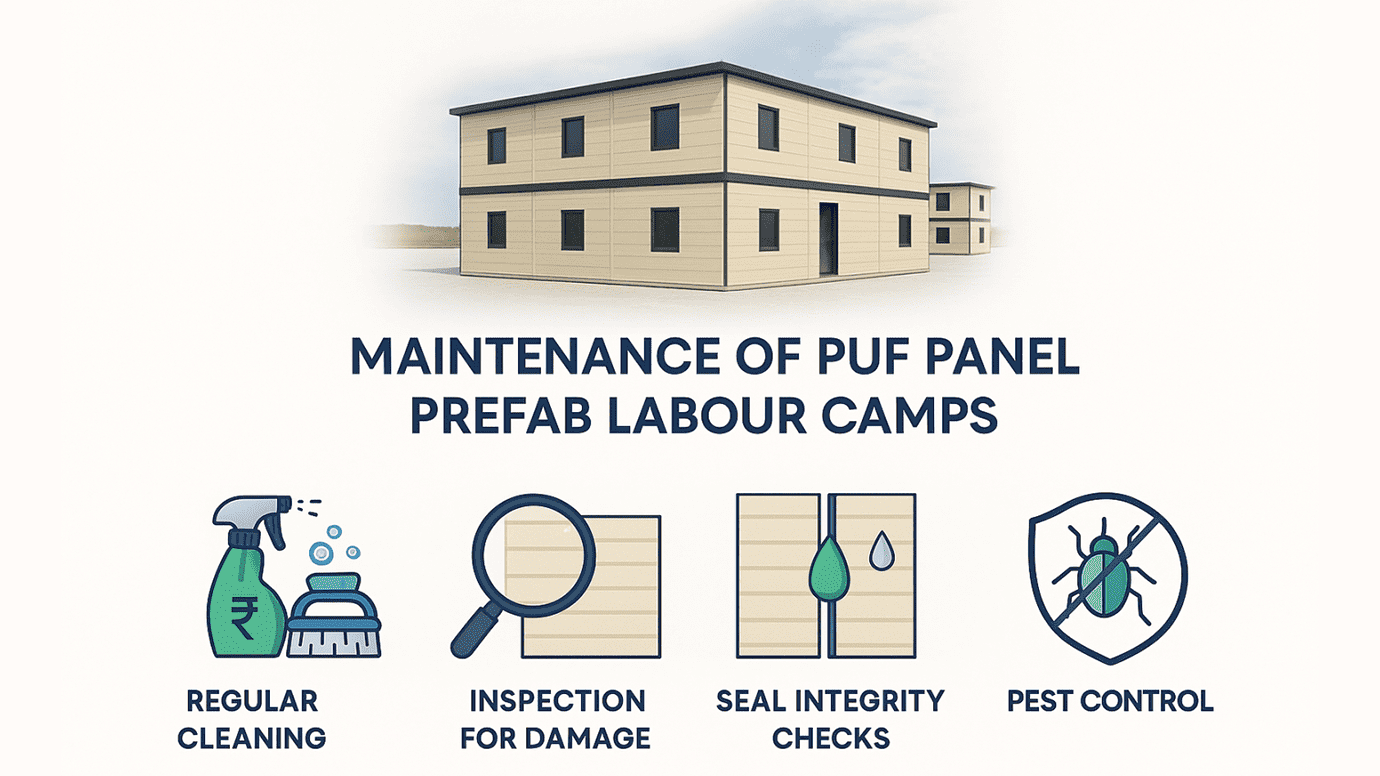

Maintenance and Lifecycle Management of PUF Panel Structures in Prefabricated Labour Camps

Effective maintenance and strategic lifecycle management are essential components in enhancing the sustainability and operational efficiency of prefabricated labour camps equipped with PUF panels. This section outlines the guidelines for maintaining these innovative structures and discusses their expected lifespan, along with environmentally conscious end-of-life recycling or disposal options.

Maintaining PUF Panel Structures in Prefabricated Labour Camps

Maintaining the PUF panels in prefabricated labour camps is relatively low-demand due to their robust nature. However, systematic inspections and maintenance are critical to ensure that these prefabricated labour camps continue to offer optimal living conditions and structural integrity throughout their usage. Essential maintenance practices include:

- Regular Cleaning: It's important to regularly clean the PUF panels in prefabricated labour camps to prevent the accumulation of dirt and debris, which can impair their insulation properties and aesthetic appearance.

- Inspection for Damage: Conducting routine inspections for any damage such as cracks, scratches, or moisture penetration is crucial. Early detection allows for immediate repairs, preventing more extensive damage and maintaining the structural efficacy of the prefabricated labour camps.

- Seal Integrity Checks: Regular checks of the seals between panels are necessary to ensure they remain air and water-tight. This maintenance is essential for preserving the thermal efficiency and overall comfort within prefabricated labour camps.

- Pest Control: Implementing consistent pest control measures is advised to protect the integrity of the PUF panels against potential pest-related damages.

Expected Lifespan of PUF Panels in Prefabricated Labour Camps

PUF panels are celebrated for their longevity, which makes them particularly suitable for prefabricated labour camps. With proper maintenance, these panels can effectively serve for several decades. Typically, the lifespan of PUF panels can extend from 30 to 40 years, depending on the environmental exposure and maintenance regularity. This durability ensures that prefabricated labour camps can be utilized for long-term projects across multiple locations, offering significant returns on investment.

End-of-Life Recycling or Disposal Options for PUF Panels

As sustainability becomes more pivotal in construction practices, managing the end-of-life of materials like PUF panels used in prefabricated labour camps becomes increasingly important. Here are some environmentally friendly ways to handle PUF panels at the end of their life:

- Recycling: The metallic components of PUF panels can be recycled and reused in the production of new materials. This recycling process helps conserve resources and reduce the environmental impact of prefabricated labour camps.

- Repurposing: Used PUF panels can sometimes be repurposed for other construction needs, such as creating temporary shelters or additional storage solutions, thereby prolonging their useful life.

- Responsible Disposal: For PUF panels that are beyond repurposing or recycling, ensuring they are disposed of responsibly is crucial. This involves transporting them to facilities equipped to handle them according to environmental safety standards.

Adhering to these maintenance and lifecycle management protocols not only extends the functional life of prefabricated labour camps but also supports environmental sustainability goals within the construction industry. These practices ensure that the camps are maintained in peak condition while minimizing their ecological footprint.

FAQs:

Q. How do prefabricated labour camps benefit from using PUF panels?

A. Prefabricated labour camps benefit from PUF panels through enhanced insulation, reduced construction time, and increased durability, making these camps cost-effective and energy-efficient.

Q. What makes PUF panels suitable for different climates in prefabricated labour camps?

A. PUF panels provide superior thermal insulation and moisture resistance, making them ideal for maintaining comfort and durability in prefabricated labour camps across various climatic conditions.

Q. Can PUF panels in prefabricated labour camps be customized?

A. Yes, PUF panels can be customized in size, thickness, and finish, allowing for tailored designs to meet specific needs in prefabricated labour camps.

Q. What are the environmental benefits of using PUF panels in prefabricated labour camps?

A. Using PUF panels helps reduce the carbon footprint of prefabricated labour camps through energy efficiency and reduced material waste during construction.

Q. How do PUF panels enhance the speed of construction for prefabricated labour camps?

A. PUF panels are pre-manufactured and easy to assemble, significantly speeding up the construction process of prefabricated labour camps compared to traditional building methods.

Q. Can PUF panel prefabricated labour camps be relocated?

A. Yes, the modular design and lightweight nature of PUF panels make prefabricated labour camps easily portable and adaptable to new locations.

Conclusion

As we have explored throughout this blog, the use of PUF panels in prefabricated labour camps represents a significant advancement in construction technology, offering numerous benefits that are transforming the way we approach building projects. These innovative panels bring forth a combination of efficiency, sustainability, and adaptability that is unmatched in traditional construction methods.

PUF panels enhance the structural integrity and functional efficiency of prefabricated labour camps. Their superior insulation properties ensure energy efficiency, which is crucial for reducing operational costs and environmental impact. Additionally, the lightweight and durable nature of PUF panels facilitates rapid construction and easy transportation, allowing for quick setup and relocation of prefabricated labour camps as needed. This flexibility is particularly beneficial in industries that require dynamic operational capabilities.

Moreover, the environmental benefits of using PUF panels cannot be overstated. They contribute significantly to the sustainability of construction projects by minimizing waste during production and reducing the energy required for heating and cooling. These factors align with the global push towards more environmentally friendly construction practices.

For businesses and organizations looking to leverage these advantages, MAKS Engineering stands ready to assist. As a leader in the construction of prefabricated labour camps, MAKS Engineering offers expert services from the initial design phase through to the final installation. Whether you are looking to construct new prefabricated labour camps or transition from traditional building methods, MAKS Engineering can provide tailored solutions that meet your specific needs.

We encourage readers to reach out to MAKS Engineering for more information on how PUF panels can be integrated into your next project. Their team of experts is equipped to handle all aspects of prefabricated labour camps installation and construction, ensuring that you receive the most effective and efficient service possible.

Embrace the transformative potential of PUF panels in your construction projects. Contact MAKS Engineering today to learn more about how prefabricated labour camps can benefit your operations, both economically and environmentally. Let’s build a more sustainable and efficient future together.

To know more about other structures, go to our Prefabricated Houses and Shelters page.