Operation Theatre Door

Operation Theatre Door

In any healthcare facility, infection control and patient safety are two of the most critical priorities. From intensive care units to surgical suites, every corner of a hospital must be designed to reduce contamination risks and maintain a sterile environment. Among these, the operation theatre door plays a vital role. Often overlooked, hospital theatre doors are not just entryways—they are protective barriers that support hygiene, safety, and efficiency in sensitive areas.

A properly engineered OT door ensures that outside contaminants are kept away from the sterile surgical zone. The right hospital operation theatre door minimizes air leakage, controls temperature variations, and reduces the possibility of cross-contamination. In fact, the quality of operation theatre door design directly influences how effectively hospitals can safeguard patients and healthcare professionals during critical procedures.

Modern hospitals are increasingly moving away from traditional materials and opting for advanced solutions such as PUF (Polyurethane Foam) panels. These panels are lightweight, durable, and highly hygienic, making them an ideal choice for operation theatre doors. By combining superior insulation with easy-to-clean surfaces, PUF panel doors provide hospitals with a reliable, long-lasting solution that not only meets but exceeds infection control standards.

What is an Operation Theatre Door?

An operation theatre door is far more than just an entry point to a surgical suite—it is a critical component of hospital infrastructure designed to protect patients and medical staff. In simple terms, hospital theatre doors serve as a barrier between the sterile environment of the operation theatre and the non-sterile areas of a hospital. The right operation theatre door design ensures that the controlled atmosphere inside the theatre is maintained, thereby reducing the chances of infection, contamination, and external interference during sensitive medical procedures.

The primary purpose of an OT door is to support hygiene and safety while allowing smooth, controlled access to doctors, nurses, and equipment. A well-engineered hospital operation theatre door must meet strict standards because even the slightest compromise in design or material can disrupt the sterile environment required for surgical success.

Key Requirements of an Operation Theatre Door

- Airtightness – A high-quality operation theatre door design prevents air leakage, ensuring that the positive pressure inside the theatre is not lost. This keeps airborne contaminants outside the surgical area.

- Hygiene – Hospital theatre doors must have smooth, non-porous surfaces that are easy to clean and disinfect. Materials like PUF panels are widely preferred for their ability to resist bacterial growth.

- Durability – Since OT doors are used frequently throughout the day, they must be sturdy enough to withstand continuous opening and closing without warping or losing functionality.

- Safety – Every hospital operation theatre door should comply with fire safety regulations and allow for quick, hassle-free operation in emergencies.

In modern healthcare settings, the role of the operation theatre door has evolved from being just a functional necessity to a specialized solution engineered for infection control, durability, and patient safety. By focusing on airtightness, hygiene, strength, and compliance, hospitals can ensure that their surgical theatres meet the highest global standards.

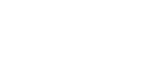

Why PUF Panels are Ideal for OT Doors

When it comes to designing a reliable operation theatre door, material selection plays a crucial role. Hospitals require doors that not only provide controlled access but also help maintain a sterile and safe environment. This is where PUF (Polyurethane Foam) panels have emerged as the most advanced and trusted solution for hospital theatre doors. Their unique properties make them the perfect choice for modern OT doors, ensuring hygiene, durability, and compliance with healthcare standards.

Thermal Insulation – Maintains Sterile Environment

An effective operation theatre door design must support precise temperature control inside the surgical area. PUF panels offer exceptional thermal insulation, which helps maintain the required sterile environment by minimizing heat transfer. This feature is especially important in hospitals, where even minor temperature fluctuations can compromise patient safety and surgical outcomes.

Hygiene & Washability – Smooth, Easy-to-Clean Surfaces

Infection control is the number one priority in any hospital. PUF panel-based hospital operation theatre doors have smooth, non-porous surfaces that prevent dust accumulation and resist bacterial growth. They are easy to wash and disinfect, ensuring that OT doors remain hygienic even with frequent cleaning. This property makes them far superior to traditional wooden or metal doors that may harbor contaminants over time.

Fire Resistance – Complies with Hospital Safety Standards

Safety is a non-negotiable requirement in healthcare facilities. A high-quality hospital theatre door must be fire-resistant to comply with safety norms. PUF panel doors are engineered to withstand fire, providing hospitals with added protection against unforeseen hazards. This feature enhances the reliability of every operation theatre door installed in critical care areas.

Durability & Lightweight – Easy Operation and Long Life

Hospitals experience continuous movement of staff, patients, and equipment, which means OT doors are used hundreds of times a day. PUF panels combine strength with lightweight properties, making the hospital operation theatre door durable yet easy to operate. This reduces wear and tear, ensuring a longer lifespan and lower maintenance costs compared to conventional door materials.

Acoustic Insulation – Reducing Noise in Sensitive Areas

A calm and quiet environment is essential in surgical theatres. PUF panel-based operation theatre doors provide excellent acoustic insulation, reducing noise from adjacent hospital areas. This not only improves concentration for surgeons and staff but also contributes to patient comfort and recovery.

In short, PUF panels transform the functionality of operation theatre doors by combining insulation, hygiene, fire safety, durability, and noise control into one solution. With such advantages, PUF panel-based hospital theatre doors are now considered the gold standard for modern healthcare infrastructure, setting new benchmarks in operation theatre door design and performance.

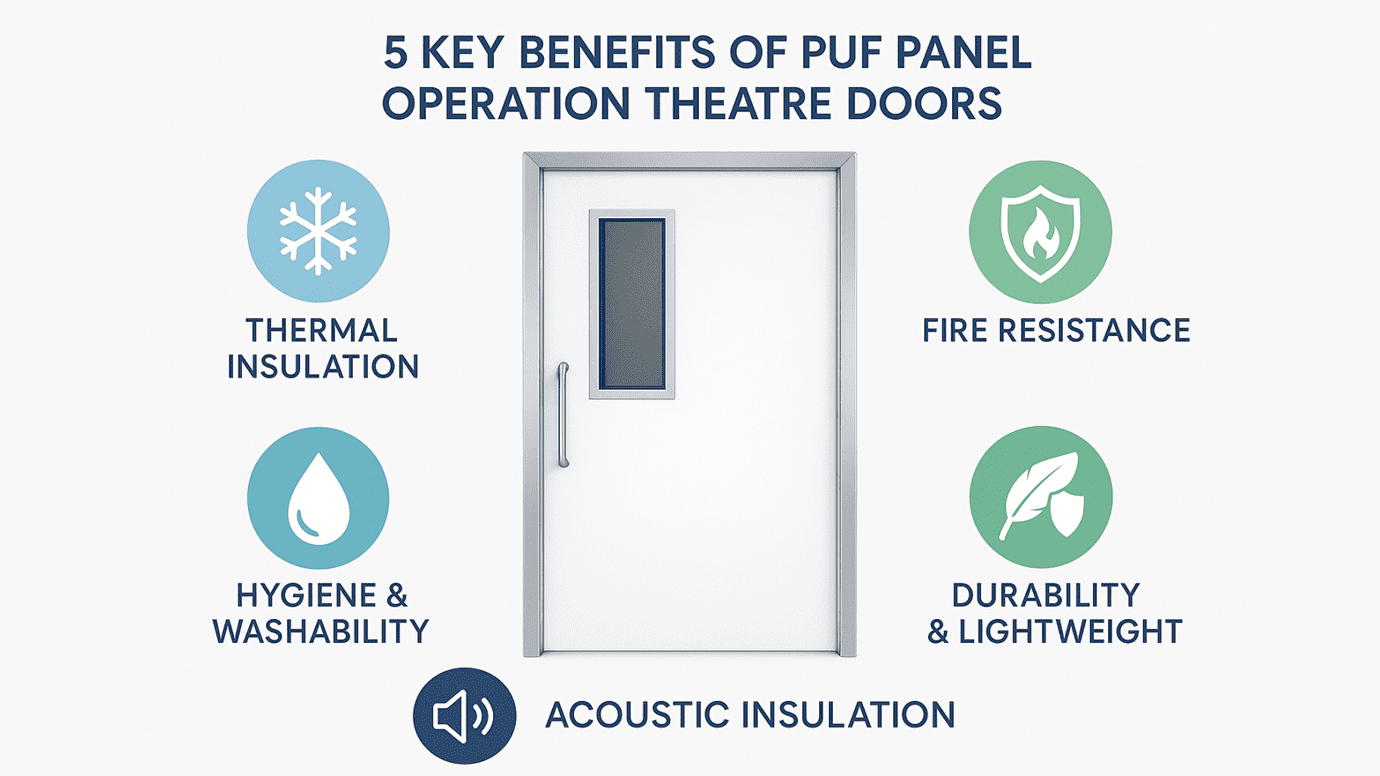

Types of Operation Theatre Doors

Every hospital has unique infrastructure requirements, and the choice of the right operation theatre door can make a significant difference in safety, hygiene, and overall functionality. Depending on the layout, available space, and sterility requirements, hospitals can select from different styles of hospital theatre doors. Below are the most widely used OT doors, each designed to meet specific needs while maintaining compliance with modern healthcare standards.

Swing OT Doors (Manual or Automatic)

The most common type of hospital operation theatre door is the swing model. These OT doors can be operated manually or equipped with automation systems for hands-free access, reducing the risk of contamination. Swing operation theatre doors are durable, easy to operate, and available in single- or double-leaf configurations. Their versatile operation theatre door design makes them suitable for most surgical environments.

Sliding OT Doors – Space-Saving and Efficient

In hospitals where space optimization is critical, sliding operation theatre doors are the ideal solution. Unlike traditional swing models, sliding hospital theatre doors move laterally, saving floor space and allowing smoother movement of stretchers, medical staff, and large equipment. These OT doors can also be automated for seamless operation, ensuring both hygiene and efficiency in busy hospital corridors.

Hermetically Sealed Operation Theatre Doors

For areas requiring the highest level of sterility—such as advanced surgical suites, ICUs, or isolation rooms—hermetically sealed hospital theatre doors are the preferred choice. This specialized design ensures airtight closure, preventing the entry of airborne particles and maintaining controlled pressure inside the theatre. Hermetic OT doors are a must-have in healthcare facilities aiming to meet international standards of infection control.

Customization Options for Hospital OT Doors

At MAKS Engineering, we understand that no two hospitals are the same. That’s why every hospital operation theatre door we manufacture can be fully customized. Options include:

- Size and Dimensions – tailored to the hospital’s infrastructure.

- Finish and Colors – powder-coated finishes and customizable shades to match hospital interiors.

- Glass View Panels – for visibility without compromising sterility.

- Automation Choices – manual, semi-automatic, or fully automatic mechanisms.

Easy Operation & Low Maintenance

Top-tier cold room doors are engineered for smooth operation, whether manual, sliding, or automatic. Their robust design ensures trouble-free performance, while minimal maintenance requirements help reduce downtime and operational costs. Reliable cold storage doors suppliers also offer after-sales support to keep these doors functioning at their best.

This level of flexibility ensures that each operation theatre door design not only meets technical requirements but also complements the hospital’s functional and aesthetic needs.

In summary, whether it’s traditional swing doors, space-saving sliding models, or advanced hermetically sealed systems, hospitals have multiple options when choosing the right OT doors. With tailored operation theatre door designs, healthcare facilities can achieve the perfect balance of safety, hygiene, and convenience.

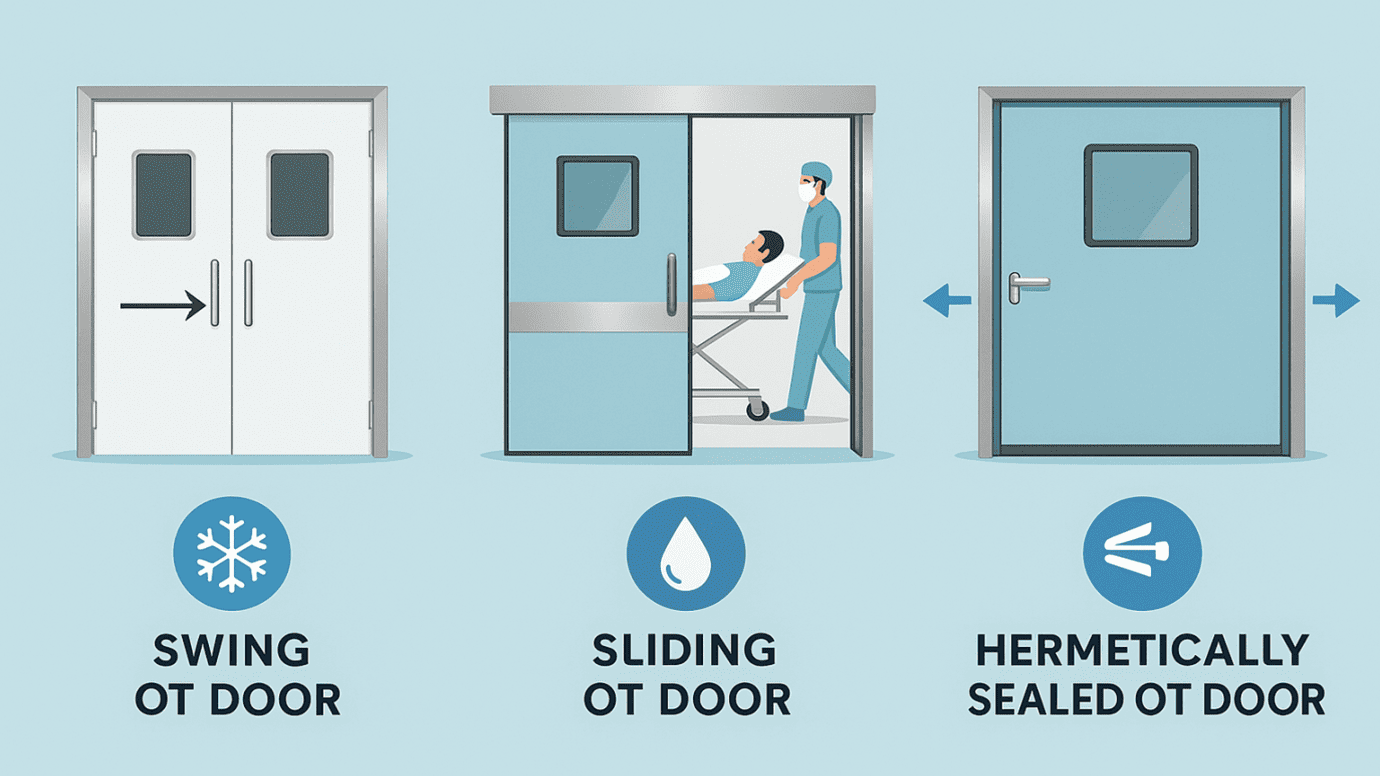

Applications Beyond Operation Theatres

While the primary purpose of an operation theatre door is to safeguard the sterility of surgical suites, their advantages extend well beyond operating rooms. Modern hospital theatre doors, especially those manufactured using PUF panels, are designed to meet the diverse requirements of healthcare and research facilities. Their durability, hygiene, and airtight operation theatre door design make them suitable for several critical environments where safety and infection control are essential.

Intensive Care Units (ICUs)

ICUs are among the most sensitive areas in any hospital. They require strict infection control, temperature stability, and controlled access. Installing high-quality OT doors in ICUs ensures a secure and sterile environment for patients who are critically ill or recovering from surgery. Just like in surgical areas, the right hospital operation theatre door in ICUs helps minimize cross-contamination and supports round-the-clock patient care.

Isolation Rooms

With the increasing need to manage infectious diseases, isolation rooms have become a standard feature in hospitals. Airtight operation theatre door designs are ideal for these spaces, as they prevent pathogens from spreading to other areas. A customized hospital theatre door with hermetic sealing ensures proper containment while still allowing safe and efficient access for healthcare professionals.

Cleanrooms and Pharma Labs

In pharmaceutical labs and cleanrooms, contamination control is a top priority. PUF panel-based hospital operation theatre doors provide excellent insulation, hygiene, and durability, making them suitable for environments where precision and purity are crucial. Whether in drug manufacturing, vaccine storage, or sterile product development, these specialized OT doors ensure compliance with international cleanroom standards.

Research and Diagnostic Centers

Modern diagnostic centers and research facilities rely on sterile conditions to ensure accuracy in testing and experimentation. By installing advanced operation theatre doors, institutions can maintain controlled environments free from external disturbances. Customized hospital theatre doors with viewing panels also allow monitoring without the need to enter, preserving sterility while improving operational efficiency.

The applications of an operation theatre door go far beyond surgical suites. From ICUs and isolation rooms to cleanrooms and research facilities, the adaptability of modern OT doors ensures safety, hygiene, and compliance across various healthcare environments. With customizable operation theatre door designs, hospitals and laboratories can achieve both functionality and long-term reliability.

Also Read: Cold Room Doors

Why MAKS Engineering is the Right Partner for PUF Panel OT Doors

Choosing the right partner for designing and installing an operation theatre door is just as important as selecting the right medical equipment for a hospital. At MAKS Engineering, we understand that hospital theatre doors are not just physical barriers but essential components that directly impact infection control, safety, and overall hospital efficiency. Our expertise in PUF panel solutions makes us a trusted choice for healthcare institutions across India.

Specialization in PUF Panel Solutions

MAKS Engineering specializes in manufacturing high-performance doors using PUF panels, a material known for its insulation, hygiene, and durability. By integrating PUF panels into every hospital operation theatre door, we ensure superior thermal control, airtightness, and washability. This specialization allows us to deliver OT doors that not only meet but often exceed healthcare compliance standards.

End-to-End Support: From Design to Installation

What sets us apart is our complete support system. We provide end-to-end solutions covering operation theatre door design, precision manufacturing, and professional installation. This seamless process ensures that every hospital theatre door we deliver is perfectly aligned with the functional needs of the facility. Our team also provides guidance on maintenance and compliance, giving hospitals complete peace of mind.

Custom-Built Solutions for Different Hospital Needs

No two hospitals are the same, and neither should their infrastructure be. MAKS Engineering offers customized OT doors that can be tailored in terms of size, finish, color, and automation features. Whether a facility requires a hermetically sealed operation theatre door for a high-sterility environment, or a space-saving sliding model for a compact area, we provide solutions that fit perfectly. Our custom-built approach ensures that every hospital operation theatre door enhances both functionality and aesthetics.

Proven Expertise and Trust

Over the years, we have partnered with leading hospitals and healthcare projects, delivering reliable and durable hospital theatre doors. Our reputation is built on quality, precision, and commitment to customer satisfaction. Hospitals trust us not just for our products but also for our professionalism and after-sales support.

In today’s healthcare environment, hospitals need more than just standard doors—they need advanced, reliable, and hygienic solutions. By choosing MAKS Engineering, hospitals gain a partner who understands the critical importance of operation theatre door design and delivers customized, PUF panel-based OT doors that meet international standards of safety and performance.

FAQs:

Q1. What is an operation theatre door and why is it important in hospitals?

A. An operation theatre door is a specially designed barrier that separates the sterile surgical area from other parts of a hospital. Unlike regular doors, hospital theatre doors are engineered to prevent contamination, maintain air pressure, and ensure safety during medical procedures.

Q2. How does an operation theatre door design help in infection control?

A. A well-planned operation theatre door design ensures airtightness and hygiene. Smooth, non-porous surfaces prevent bacterial growth, while proper sealing reduces the risk of airborne contaminants entering the surgical zone.

Q3. What makes PUF panel OT doors better than traditional hospital doors?

A. PUF panel-based OT doors provide superior insulation, fire resistance, and easy washability compared to traditional wooden or metal doors. This makes a hospital operation theatre door built with PUF panels more hygienic and long-lasting.

Q4. Do OT doors help in noise reduction inside operation theatres?

A. Yes, high-quality OT doors built with PUF panels provide acoustic insulation. This minimizes external noise, allowing surgeons and staff to focus while maintaining a calm surgical environment.

Q5. How durable are hospital theatre doors made from PUF panels?

A. PUF panel hospital theatre doors are lightweight yet strong. Their durability ensures that each operation theatre door can withstand frequent use in hospitals without losing performance or requiring heavy maintenance.

Q6. What are PUF panel doors and why are they used in hospitals?

A. PUF panel doors are made with polyurethane foam for superior insulation, durability, and hygiene. They are widely used in hospitals for operation theatre doors, cold rooms, and cleanrooms because they help maintain sterile, temperature-controlled, and contamination-free environments. For more information, you can read our detailed blog on PUF Panel Door.

Conclusion

The importance of an operation theatre door in a hospital cannot be overstated. It is not merely an entryway but a vital safety feature that protects patients, staff, and equipment by maintaining sterile conditions. Modern hospital theatre doors, especially those constructed with PUF panels, offer unmatched performance by combining hygiene, durability, and compliance with global healthcare standards.

By installing the right OT doors, hospitals gain multiple advantages. They ensure hygiene through smooth, non-porous surfaces that resist bacterial growth and allow easy cleaning. They provide durability, standing up to the constant movement of staff and equipment with minimal wear and tear. They enhance safety with fire-resistant construction, meeting strict healthcare norms. And they guarantee compliance with NABH, WHO, and international guidelines, making them a reliable choice for critical environments.

Every hospital operation theatre door must be thoughtfully engineered to preserve sterility while enabling ease of movement for doctors and nurses. A carefully designed operation theatre door design improves efficiency during surgeries, reduces infection risks, and contributes to patient comfort and safety.

If you are planning to upgrade your healthcare infrastructure or setting up a new facility, investing in premium-quality operation theatre doors is an essential step. MAKS Engineering specializes in custom-built, PUF panel-based hospital theatre doors that deliver both functionality and innovation.

For more information regarding PUF Panels and other types of doors and structures made from it, you can go to our Homepage.