PPGI vs PPGL Sheets

PPGI vs PPGL Sheets: Which is better for Your PUF Panel Building Project?

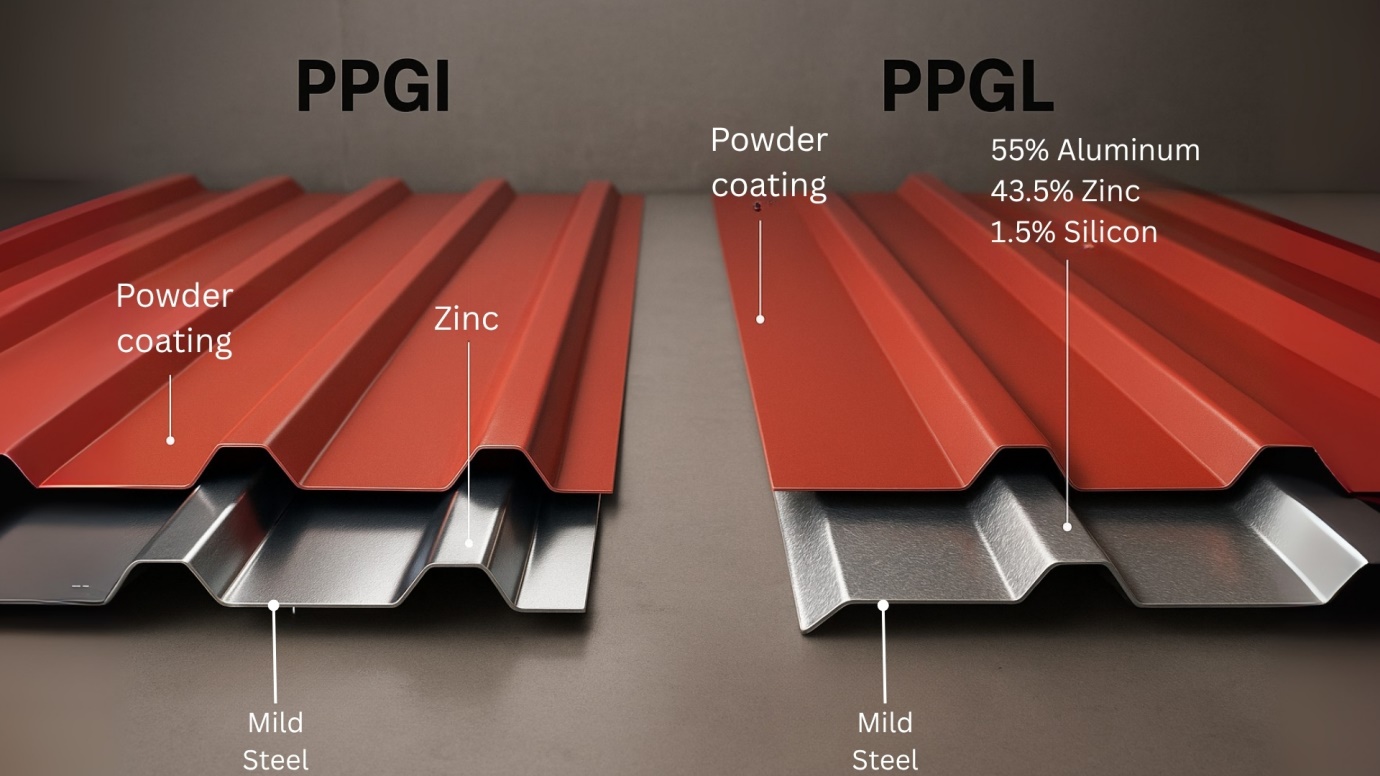

In today’s fast-evolving construction landscape, PUF panels (Polyurethane Foam Panels) have become an essential choice for building modern, energy-efficient structures. Whether it’s a cold room, site office, cleanroom, warehouse, or prefabricated home, PUF panels offer an ideal balance of insulation, structural integrity, and quick installation. However, the real performance and lifespan of a PUF panel greatly depend on its outer cladding material.

The outer skin of a PUF panel is typically made from either a PPGI sheet or a PPGL sheet. These are pre-coated steel sheets that not only protect the insulation core but also enhance the durability, aesthetics, and thermal performance of the entire structure.

Choosing between PPGI and PPGL is critical for long-term success in PUF panel applications. While both materials are widely used, they differ significantly in terms of corrosion resistance, heat durability, and cost-effectiveness. For example, a PPGI PUF panel may be suitable for indoor or mild climate applications, while a PPGL sheet may be better suited for coastal or high-humidity regions.

The debate between PPGL vs PPGI is one that every architect, builder, or facility manager must carefully evaluate when planning a project. With the right choice, you ensure better structural performance, longer lifespan, and lower maintenance costs. At Maks Engineering, we specialize in installing high-performance PUF panels backed by expert guidance on whether to use PPGI or PPGL for your specific application.

In this blog, we’ll break down the difference between a PPGI sheet and a PPGL sheet, so you can make an informed decision that adds value to your building project.

What Are PPGI and PPGL Sheets?

When it comes to building reliable, long-lasting PUF panels, the choice of cladding material plays a critical role. Two of the most widely used outer skins in PUF panel manufacturing are PPGI and PPGL sheets. These coated steel products not only provide structural strength but also protect the insulation core from environmental exposure. Let’s take a closer look at what they are and how they differ.

What is PPGI?

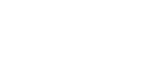

PPGI, short for Pre-Painted Galvanized Iron, refers to a category of coated steel products made from cold-rolled steel, which is then hot-dip galvanized with a layer of zinc (Zn) and finished with a paint coating. These pre painted galvanized iron sheets are popular for their corrosion resistance, cost-effectiveness, and aesthetic flexibility.

Structurally, a PPGI steel sheet is composed of:

- A base layer of cold rolled steel

- A zinc metallic coating for corrosion protection

- A topcoat of polyester, SMP, or PVDF paint for color, gloss, and UV resistance

Pre painted gi sheet is another common term used for PPGI in the construction and roofing industry. These sheets are used extensively in roofing, wall cladding, cleanroom panels, and PUF panel exteriors, especially in non-coastal or dry environments where moderate corrosion resistance is sufficient.

What is PPGL?

On the other hand, PPGL stands for Pre-Painted Galvalume, a coated steel product that offers superior corrosion resistance compared to PPGI. A pre painted galvalume sheet features a metallic coating made from a zinc-aluminum alloy (usually 55% aluminum, 43.5% zinc, and 1.5% silicon). This alloy offers the combined benefits of zinc’s sacrificial protection and aluminum’s barrier protection, making PPGL steel ideal for coastal, industrial, or high-humidity regions.

Like PPGI, PPGL is manufactured using:

- A cold-rolled steel base

- A 55% Al-Zn-Si metallic coating

- A pre-painted layer for durability and appearance

The result is a highly durable, reflective, and longer-lasting product that’s gaining popularity in modern architectural and industrial applications.

In summary, pre painted galvanized iron sheets (PPGI) and pre painted galvalume sheet (PPGL) are engineered for different performance levels and environmental conditions. Choosing between ppgi steel and ppgl steel depends on your building’s location, lifespan expectations, and budget.

Deep-Dive Comparison: PPGI vs PPGL

When selecting the best outer cladding for PUF panels, understanding the differences between a PPGI sheet and a PPGL sheet is essential. While both materials are widely used in modern construction, their performance varies depending on the coating composition, environmental exposure, and application. Below is a side-by-side comparison to help you make an informed decision.

Feature | PPGI (Pre-Painted Galvanized Iron) | PPGL (Pre-Painted Galvalume) |

Metallic Coating Composition | Zinc (Zn) coated steel | 55% Aluminum + 43.5% Zinc + 1.5% Silicon (Galvalume) |

Corrosion Resistance | Moderate – ppgi sheet relies on sacrificial protection from zinc | Excellent – ppgl sheet offers both barrier and sacrificial protection |

Heat Resistance | Stable up to ~200°C | Superior – withstands up to ~315°C with minimal degradation |

Formability | Highly flexible and easy to bend and roll | Good, but slightly stiffer due to aluminum content |

Lifespan in PUF Panels | ~10–15 years in moderate climates | ~20–25 years in harsh or coastal conditions |

Cost | More economical – ideal for budget-sensitive projects | Higher upfront cost, but better ROI over the long term |

Recommended Environments | Ideal for dry, inland areas, temporary buildings, interior use | Best suited for coastal, humid, industrial, or outdoor structures |

Choosing between a ppgi sheet and a ppgl sheet boils down to application environment, budget, and performance expectations. While PPGI is excellent for general-purpose construction and interior applications, PPGL is the go-to for demanding, weather-exposed, and high-humidity projects.

By partnering with Maks Engineering, you get expert guidance on whether a ppgi puf panel or ppgl puf panel is ideal for your unique needs.

Technical Insight: How Do They Perform in Real Conditions?

Understanding how PPGI and PPGL materials perform in real-world environments is essential when designing durable and energy-efficient PUF panel structures. Beyond just composition, it’s their technical performance under stress, heat, and environmental exposure that determines longevity and reliability.

Here’s a deep technical look at how a PPGI panel and a PPGL colour coated sheet behave during real-time installation and usage.

Corrosion Behavior: Sacrificial vs. Barrier Protection

The primary distinction lies in how these materials fight corrosion. A PPGI colour coated sheet is made from pre painted galvanized iron, where the zinc coating offers sacrificial protection. This means the zinc corrodes before the base steel does, protecting it temporarily. While effective in dry or mildly humid environments, this protection tends to wear off faster in marine or industrial zones.

On the other hand, a PPGL colour coated sheet includes a Galvalume coating (55% aluminum, 43.5% zinc), which provides dual protection—aluminum acts as a barrier, forming a stable oxide layer, while zinc offers sacrificial backup. This results in significantly better corrosion resistance, especially in coastal, chemical, or high-moisture conditions.

Verdict: If you're installing panels in aggressive environments, a PPGL colour coated sheet offers superior protection and longer service life.

Heat Resistance in Hot Industrial Zones

Heat resistance is critical for structures exposed to direct sunlight, industrial machinery, or high ambient temperatures. A PPGI panel performs well up to around 200°C but tends to lose paint adhesion and degrade when exposed to sustained high temperatures.

In contrast, a PPGL colour coated sheet can withstand temperatures up to 315°C without paint peeling, chalking, or metal fatigue. Thanks to the aluminum component, it reflects radiant heat more effectively—improving thermal efficiency in hot zones like manufacturing plants, rooftops, and warehouses.

Verdict: For heat-exposed facilities, PPGL ensures better thermal stability and insulation support for the PUF core.

Edge Protection & Paint Adhesion

During fabrication, especially when roll-forming or cutting panels, the sheet’s edge behavior matters. A PPGI panel, being more ductile, maintains better paint integrity around cut edges and forms cleaner bends, especially when using pre painted galvanized iron of good quality.

However, PPGL colour coated sheets may require more attention during cutting, as the aluminum content can reduce edge coating adhesion. Unsealed edges are more prone to localized corrosion if not properly handled. Yet, when manufactured correctly and installed by experienced professionals (like Maks Engineering), both materials perform reliably with proper sealing and edge finishing.

Verdict: PPGI offers slightly better paint adhesion at cut edges, but PPGL remains highly durable when installed with care.

Mechanical Strength During Roll Forming and Cutting

From an installation and manufacturing standpoint, a PPGI colour coated sheet offers superior formability. It bends easily into corrugated or interlocking profiles without cracking the paint layer, making it ideal for custom PUF panel shapes and on-site modifications.

Although PPGL colour coated sheets are slightly stiffer due to the aluminum content, they still perform well with the right tools. The key difference lies in tool wear—PPGL may be a bit more abrasive, requiring hardened blades and precision equipment.

Verdict: PPGI wins on ease of fabrication, while PPGL offers durability with minimal compromise when processed properly.

In summary, the technical performance of both PPGI and PPGL sheets depends on your specific project needs. If your structure is indoor, temporary, or cost-driven, PPGI offers ease of fabrication and satisfactory protection. For long-term, exterior, industrial, or humid environments, PPGL delivers unmatched resilience, heat resistance, and long-term value.

Real-World Applications: Which One Should You Choose?

When choosing the right cladding material for a PUF panel, the decision goes beyond just technical specifications—it’s about real-world performance, budget alignment, and environmental compatibility. Whether you’re building a temporary office, a coastal facility, or a cold storage unit, selecting between a PPGI PUF panel and a PPGL PUF panel can dramatically affect the structure’s lifespan, thermal performance, and maintenance cost.

At Maks Engineering, we help clients match materials to applications based on geography, function, and durability requirements. Below is a use-case-driven guide to help you decide.

Temporary Site Offices ➜ PPGI

For short-term or relocatable constructions like project site offices, security cabins, or lab enclosures, a PPGI PUF panel is the perfect choice. It is cost-effective, easy to fabricate, and quick to install. Its excellent formability allows the creation of versatile shapes such as PPGI corrugated sheet and PPGI profile sheet—making it ideal for both walls and partitions.

Coastal Prefab Buildings ➜ PPGL

Structures located in coastal zones, near saltwater bodies, or in high-humidity climates require extra corrosion resistance. Here, a PPGL roofing sheet offers outstanding protection against rust, moisture, and UV degradation. The aluminum-zinc coating ensures the building lasts significantly longer, even with minimal upkeep. Use PPGL profile sheet for roofing and cladding where aesthetics and endurance are priorities.

Industrial Cleanrooms ➜ PPGL

Cleanrooms in pharmaceutical, food processing, and electronics industries demand materials that resist both chemical exposure and moisture infiltration. PPGL profile sheet cladding combined with PUF insulation offers an ideal solution. Its superior barrier protection and non-porous surface help maintain sterile and temperature-controlled environments.

Rooftops and Sun-Exposed Walls ➜ PPGL

In sun-facing applications like rooftop panels, canopies, and external facades, exposure to UV radiation and thermal stress is a major concern. A PPGL roofing sheet handles heat up to 315°C, keeping both paint and metal structure intact. It also reflects more heat due to the aluminum content, improving energy efficiency in residential and commercial buildings.

Cold Storages ➜ PPGI or PPGL (Based on Budget & Location)

Cold storage applications vary widely in size, climate, and usage frequency. If your unit is located inland and budget is tight, a PPGI PUF panel made from PPGI sheet can offer satisfactory performance. For coastal cold storages, high-end units, or long-term installations, we recommend a PPGL-based solution due to its superior corrosion and moisture resistance.

Your choice between a PPGI PUF panel and a PPGL PUF panel should be guided by your project’s lifespan expectations, climate, and functionality. With a range of formats like corrugated sheet, and profile sheet, Maks Engineering helps clients create customized, durable, and cost-effective PUF panel installations for every application—from portable cabins to permanent industrial sites.

FAQs:

Q. What is the difference between PPGI and PPGL?

A. The key difference between PPGI and PPGL lies in their metallic coatings. PPGI sheets are coated with zinc (galvanized), while PPGL sheets use a 55% aluminum, 43.5% zinc (galvalume) coating. This makes PPGL more corrosion-resistant, especially in coastal or humid environments.

Q. Which material is more suitable for coastal areas—PPGI or PPGL?

A. PPGL is the preferred choice for coastal environments due to its superior corrosion resistance. The aluminum-zinc coating on a PPGL sheet provides excellent protection against saltwater, making it ideal for prefab buildings near the sea.

Q. Is PPGI a good option for temporary buildings?

A. Yes, a PPGI PUF panel is perfect for temporary site offices, storage units, and project cabins. It is affordable, easy to fabricate, and quick to install, especially when using PPGI profile sheet or PPGI corrugated sheet formats.

Q. Can PPGL handle high heat in industrial zones?

A. Absolutely. A PPGL sheet can withstand temperatures up to 315°C, making it ideal for rooftops, hot machinery sheds, and sun-exposed structures. This is why many clients prefer PPGL roofing sheet for industrial applications.

Q. Can I use PPGI panels for cold storages?

A. Yes, PPGI PUF panels are commonly used in cold storage rooms, especially when located in non-coastal areas. For high-moisture environments, however, PPGL may offer better durability.

Q. What type of panel is best for cleanrooms in the pharma or food industry?

A. PPGL profile sheet is the preferred choice for cleanroom cladding, thanks to its moisture resistance, smooth surface, and non-reactive coating—perfect for maintaining hygiene and temperature control.

Q. Is a PPGI sheet suitable for roofing?

A. Yes, a PPGI sheet can be used for roofing in mild climates. However, for extended durability, especially in sun-exposed or humid regions, a PPGL roofing sheet is recommended.

Q. Can I use PPGI in areas with chemical fumes or pollution?

A. PPGI may not perform well in chemical or industrial environments where corrosive agents are present. In such cases, PPGL is the better option because of its dual-layer corrosion protection.

Q. What’s the difference between PPGI corrugated and plain sheets?

A. A PPGI corrugated sheet has a wavy or ribbed surface for added rigidity, commonly used in roofing and walls. A PPGI plain sheet, on the other hand, has a flat surface and is often used for custom panel cutting or interior walls.

Q. How can Maks Engineering help me choose between PPGI and PPGL?

A. At Maks Engineering, we offer expert guidance on choosing between PPGI vs PPGL based on your site’s climate, usage, and budget. Whether you need a fast-install PPGI PUF panel or a durable PPGL roofing sheet, we ensure a solution tailored to your project.

Conclusion

Choosing the right cladding material for your PUF panel construction project is more than a technical decision—it’s a strategic investment in your building’s performance, durability, and cost-efficiency. As we’ve explored in this comparison, the debate between PPGI vs PPGL is not about which material is universally better, but about which one is better suited for your specific application and environment.

A PPGI-based panel is a smart choice for budget-sensitive projects, indoor structures, or temporary site offices where corrosion and heat exposure are minimal. Its ease of fabrication and cost-effectiveness make it a reliable solution for many standard construction needs.

However, if your project involves coastal regions, industrial zones, or extreme weather exposure, then a PPGL solution is the better long-term investment. Thanks to its aluminum-zinc coating, PPGL delivers superior corrosion resistance, thermal stability, and low maintenance requirements, making it ideal for rooftops, exterior walls, and cleanrooms.

Understanding the strengths and limitations of each material in the PPGI vs PPGL debate allows you to make an informed decision that aligns with your project’s demands and budget.

At Maks Engineering, we don’t just install PUF panels—we help you select the right material based on site conditions, usage expectations, and lifecycle value. Whether you need a fast, flexible PPGI installation or a long-lasting, weather-resistant PPGL solution, our team provides expert consultation and turnkey support from concept to completion.

Let’s Build Smarter, Together

Not sure which material suits your project best? Contact us today for personalized recommendations, site analysis, and professional PUF panel installation services backed by industry expertise.

To learn more about our range of PUF panels, other PUF Panel structures, and our installation services, feel free to visit our Homepage.