PUF Panel Banana Ripening Chambers

PUF Panel Banana Ripening Chambers

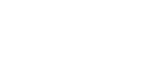

Bananas are among the world’s most beloved fruits, consumed globally not just for their flavour but also for their nutritional benefits. However, achieving that perfect state of ripeness is crucial for the best taste and texture. Banana ripening is a delicate process that transforms the fruit from hard and green to soft and yellow, enhancing its sweetness and aroma. This transformation is often accelerated and optimized in controlled environments known as banana ripening chambers.

The use of banana ripening chambers has revolutionized how retailers, wholesalers, and even large-scale farmers manage the post-harvest life of bananas. These specialized chambers allow for precise control over the internal conditions, such as temperature, humidity, and ethylene concentration, facilitating a uniform and predictable ripening process. This controlled environment not only ensures high-quality bananas that meet consumer expectations but also significantly reduces spoilage.

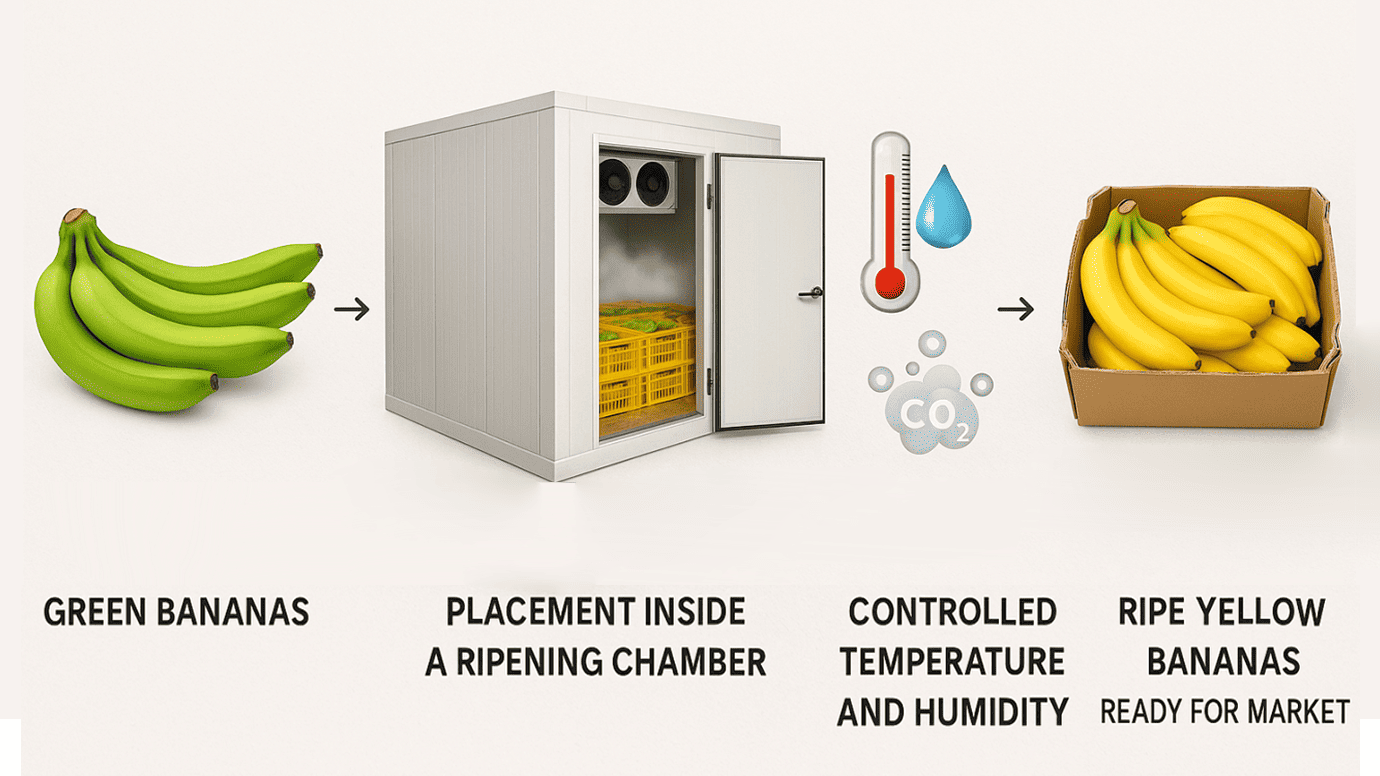

A key component in the construction and efficiency of these chambers is the use of PUF (Polyurethane Foam) panels. In the banana ripening chamber design, PUF panels play a critical role by providing excellent insulation. This helps in maintaining the specific temperatures and humidity levels essential for optimal ripening. The integration of PUF panels in banana ripening chambers ensure that the ripening process is energy-efficient, cost-effective, and environmentally friendly.

What Are Banana Ripening Chambers?

Banana ripening chambers are specialized facilities designed to control the environmental conditions that influence the ripening of bananas. These chambers are an essential part of post-harvest management in the banana industry. By using banana ripening chambers, distributors and producers can manage the ripening process to ensure that bananas reach consumers in optimal condition, balancing ripeness with shelf life to reduce waste and increase consumer satisfaction.

The core functionality of banana ripening chambers involves the controlled application of ethylene, a naturally occurring plant hormone that accelerates the ripening process. In a typical banana ripening chamber, bananas are exposed to a precise concentration of ethylene gas in a controlled environment. This exposure triggers the natural ripening mechanisms within the fruit, converting starches into sugars, softening the flesh, and changing the peel from green to yellow.

The banana ripening chamber design includes features that maintain specific levels of temperature and humidity, which are critical for effective ethylene-induced ripening. Properly designed banana ripening rooms ensure that the ethylene is evenly distributed and that each banana receives uniform exposure, resulting in consistent ripeness across batches.

There are numerous benefits to using these controlled environments for ripening bananas:

Consistency and Quality Control

Banana ripening chambers provide a consistent environment that can be finely tuned to ensure that all bananas ripen uniformly, thereby enhancing the quality and appeal of the fruit.

Reduced Spoilage

By controlling the ripening process, banana chambers help reduce the incidence of over-ripening and spoilage, significantly cutting down waste and financial losses.

Year-Round Supply

Banana ripening plants allow for the storage of unripe bananas and controlled ripening based on market demand, enabling a stable supply throughout the year, regardless of the season.

Efficiency and Scalability

With a controlled banana ripening process, producers can handle larger volumes of fruit in a more efficient manner, optimizing both space and energy use compared to natural ripening.

Banana ripening chambers are vital in the modern agricultural landscape. They provide the infrastructure needed for efficient, economical, and environmentally friendly ripening of bananas, ensuring that this popular fruit continues to meet market demands with minimal loss and maximum quality.

Understanding PUF Panels

In the context of banana ripening chambers, the use of PUF (Polyurethane Foam) panels is a key element that enhances the efficiency and effectiveness of these specialized facilities. PUF panels are advanced insulation materials that play a pivotal role in the construction and operation of banana ripening chambers.

PUF panels are made from polyurethane foam, an excellent insulator that is sandwiched between layers of structural materials such as steel or aluminium. This construction gives PUF panels their remarkable properties of high thermal resistance and robustness, which are crucial for maintaining the precise environmental controls required in banana ripening chambers.

The properties of PUF panels that make them particularly suitable for banana ripening chambers include:

- Superior Insulation: PUF panels provide outstanding thermal insulation, which is essential in banana ripening processes where maintaining specific temperature ranges is crucial. This insulation helps in minimizing energy consumption by keeping external heat out and maintaining the internal environment with less cooling effort.

- Durability: The structural strength of PUF panels ensures long-term durability, making them a cost-effective solution for building banana ripening plants. They are resistant to moisture, pests, and most chemicals, reducing maintenance costs and extending the lifespan of the ripening chambers.

- Air Tightness: PUF panels offer excellent air tightness, which prevents the leakage of ethylene gas used in the ripening process. This containment enhances the effectiveness of ethylene application, ensuring that the banana ripening process is both uniform and efficient.

- Lightweight and Easy to Install: Inspite of their strength and insulative properties, PUF panels are relatively lightweight and easy to install, which simplifies the construction of banana ripening chambers. Their modular design allows for quick assembly and disassembly, facilitating easier modifications and expansions of existing facilities.

- Cost Efficiency: By improving energy efficiency and reducing the need for frequent repairs or replacements, PUF panels lower the overall operational costs of maintaining banana ripening chambers. This makes them a more economically viable option compared to other insulating materials.

- Environmental Impact: PUF panels contribute to sustainability efforts as they help in reducing the energy consumption of banana ripening plants. Their insulating properties mean less energy is needed to maintain optimal conditions, thus reducing the carbon footprint associated with the ripening process.

In comparison to other materials like fiberglass or rock wool, PUF panels offer superior insulation, enhanced durability, and greater cost-efficiency, making them the preferred choice in modern banana ripening chamber design. Their usage not only optimizes the ripening process but also contributes to the overall sustainability and profitability of banana distribution operations.

The Role of PUF Panels in Banana Ripening Chambers

PUF panels, or Polyurethane Foam panels, are integral to the construction and functionality of banana ripening chambers, playing a pivotal role in ensuring the efficiency and effectiveness of these specialized facilities. Their use in banana chamber designs is not just a matter of structural necessity but a strategic choice for optimizing the ripening process and ensuring the production of high-quality bananas.

Construction and Insulation

PUF panels offer extensive customization options which make them particularly appealing for use in prefabricated labour camps. These panels can be manufactured in various sizes and thicknesses, accommodating different insulation requirements and structural loads. Furthermore, the outer layers of the panels can be finished with a variety of materials, colors, and textures, allowing for aesthetic integration into local environments or adherence to corporate branding.

Energy Efficiency

The energy efficiency of PUF panels comes from their high R-value, which measures an insulating material's resistance to heat flow. The higher the R-value, the better the insulation, and PUF panels rank high on this scale. This property is vital in banana ripening chambers where maintaining a precise temperature range is crucial. Efficient insulation ensures that less energy is used in maintaining these temperatures, reducing the operational costs associated with banana ripening chambers and decreasing the environmental impact of these operations.

Consistency in Temperature

The ability of PUF panels to provide consistent temperature control is another critical factor in their role within banana ripening chambers. Ethylene gas, used to induce ripening, is most effective at a narrow temperature range, typically around 14-18°C (57-64°F). PUF panels help maintain this range steadily, irrespective of external temperature conditions. This consistency is essential for ensuring that all bananas within the chamber ripen at the same rate and to the same degree of quality.

Impact on Quality and Uniformity

The uniformity of temperature and environmental control provided by PUF panels directly impacts the quality and uniformity of the bananas ripened within these chambers. Consistent exposure to controlled conditions means that each banana experiences the same ripening process, leading to uniform color, texture, and taste. This uniformity is crucial for banana distributors and retailers, as it ensures that consumers receive a consistently high-quality product. Furthermore, the controlled environment reduces the risk of premature ripening or decay, which can occur due to temperature fluctuations or uneven ethylene distribution in less well-designed banana ripening rooms.

In summary, the role of PUF panels in banana ripening chambers extends beyond simple construction elements to crucial components that enhance the ripening process’s energy efficiency, consistency, and effectiveness. The use of these panels ensures that banana ripening chambers are not only economically viable but also produce a high-quality, uniform product, essential for meeting consumer expectations in a competitive market. By integrating PUF panels into the banana ripening chambers, producers can achieve a delicate balance between operational efficiency and product quality, making these panels indispensable in modern agricultural practices.

Design and Construction of Banana Ripening Chambers

The design and construction of banana ripening chambers are critical to ensuring the effective and efficient ripening of bananas. These specialized facilities, often referred to as banana ripening chambers or banana ripening rooms, require meticulous planning around several key considerations including size, temperature controls, and ethylene distribution systems. Utilizing PUF panels during construction significantly enhances the insulation properties, contributing to the overall performance of the banana ripening process.

Key Design Considerations of Banana Ripening Chambers

- Size: The size of banana ripening chambers must be carefully planned to handle the desired volume of bananas while maintaining energy efficiency. The dimensions of the banana ripening room should not only meet current demands but also allow for future scaling, ensuring that the banana chamber remains efficient regardless of increased capacity.

- Temperature Controls: In banana ripening chambers, temperature control is paramount. The optimal temperature for banana ripening typically ranges from 14°C to 18°C, and maintaining this range is crucial. PUF panels are instrumental in this aspect, as their superior insulation helps to stabilize internal temperatures, enhancing the energy efficiency of banana ripening chambers.

- Ethylene Distribution Systems: Ethylene plays a vital role in the banana ripening process. The banana ripening chamber must include an effective ethylene distribution system to ensure even distribution of the gas, which facilitates uniform ripening. The system's design should integrate well-placed ethylene generators and fans within the banana ripening room to achieve this goal.

Steps Involved in Construction of Banana Ripening Chambers Using PUF Panels

- Planning and Layout: Initial steps in building a banana ripening chamber involve detailed planning of the layout to accommodate the necessary equipment and systems while optimizing the use of space. This stage sets the groundwork for an efficient banana ripening plant.

- Installation of Insulation Panels: The walls, ceiling, and floor of the banana ripening chamber are typically constructed using PUF panels. These panels are essential for maintaining the required insulative properties and are assembled to ensure complete sealing and thermal integrity of the banana ripening room.

- Setting Up Temperature and Humidity Controls: Installing sophisticated temperature and humidity controls is next. These systems are crucial for creating the precise environment needed within the banana chamber, controlling factors critical to the banana ripening process.

- Ethylene System Installation: Proper installation of the ethylene distribution system is imperative for even ripening. This step involves integrating ethylene generators and distribution fans strategically within the banana ripening room to maintain consistent ethylene levels throughout the chamber.

- Testing and Calibration: Once construction is completed, the banana ripening chambers undergo rigorous testing and calibration to ensure that all systems function as expected. This phase is crucial to verify that the banana ripening process is optimized for uniform ripening.

- Final Review and Safety Checks: The last step involves a thorough review and safety check to ensure that all aspects of the banana ripening chamber design meet the required standards and are safe for operation. This includes electrical and mechanical safety inspections of the banana ripening plant.

By focusing on these detailed aspects of the banana ripening chamber design and construction, and utilizing PUF panels for their superior insulative properties, producers can significantly enhance the efficiency, effectiveness, and sustainability of their banana ripening chambers.

Maintenance Tips for Banana Ripening Chambers

Proper maintenance is crucial for the optimal functioning of banana ripening chambers. Regular upkeep not only extends the lifespan of these facilities but also ensures that the banana ripening process remains efficient and effective. Here are several best practices for maintaining banana ripening chambers, designed to keep your banana ripening plant in top operational condition.

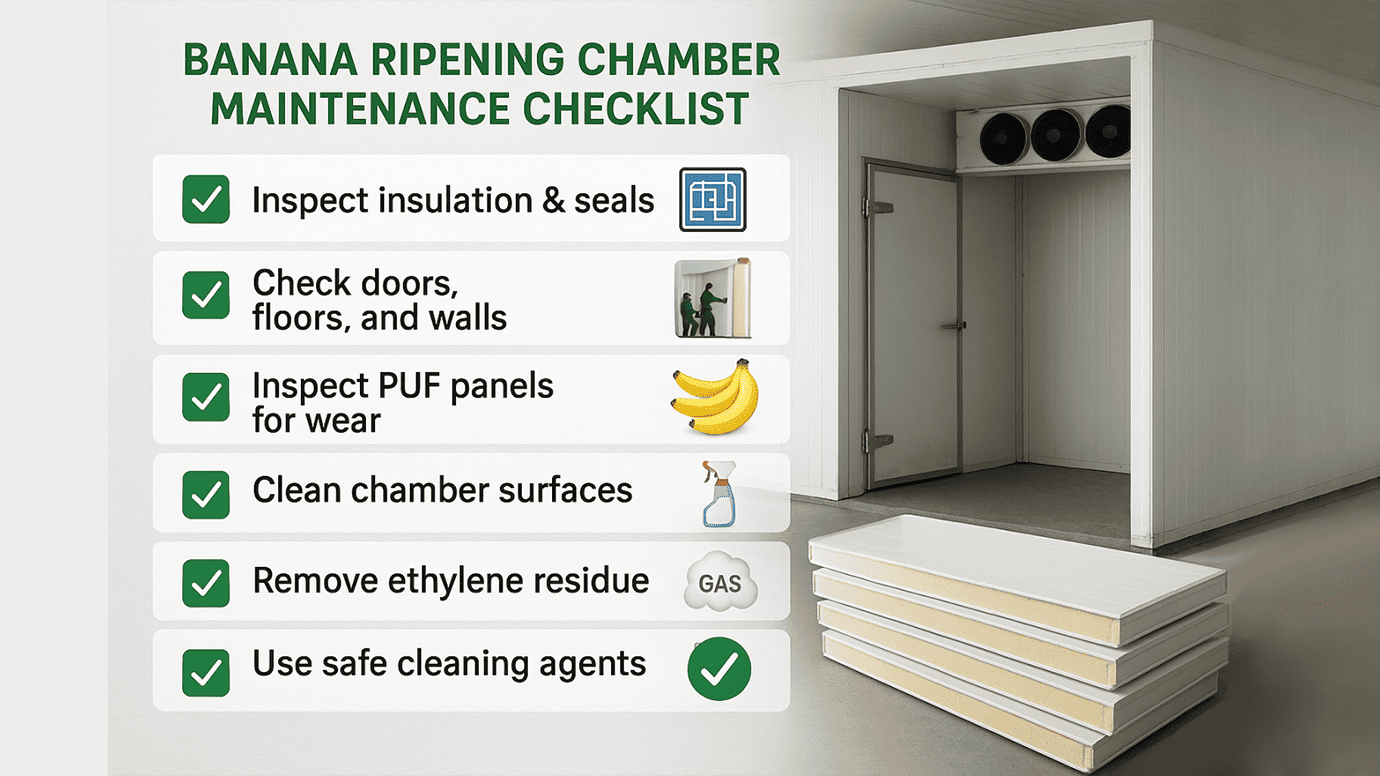

Regular Inspection and Cleaning

- Routine Inspections: Conduct regular inspections of the banana ripening chambers to check for any signs of wear and tear or mechanical issues. Focus on the integrity of insulation, seals, and the structure of PUF panels used in the banana ripening chamber design. Ensure that all components, such as doors, floors, and walls, are in good condition.

- Cleaning Protocols: Keeping the banana ripening room clean is vital. Regular cleaning helps prevent the buildup of ethylene residue and bacterial growth, which can affect the quality of the bananas. Use recommended cleaning agents that are safe for the materials used within the chamber, especially the surfaces of PUF panels.

Temperature and Humidity Control Management

- Calibration of Controls: Regular calibration of temperature and humidity sensors ensures that they provide accurate readings, which is essential for the precise management required in the banana ripening process. Misreadings can lead to improper ripening conditions, adversely affecting fruit quality.

- Ventilation Checks: Effective ventilation is crucial in maintaining the appropriate ethylene levels and air quality within banana ripening chambers. Ensure that ventilation systems are clear of obstructions and functioning correctly to support the uniform distribution of ethylene and maintain air freshness.

Ethylene and Equipment Management

- Ethylene System Maintenance: Regular maintenance of the ethylene gas generators and distribution systems is necessary to ensure they operate efficiently and safely. Check for leaks and ensure all connections are secure, as ethylene is critical in the banana ripening chambers.

- Equipment Servicing: Maintain all mechanical and electrical systems, including fans, refrigeration units, and control panels for banana ripening chambers. Scheduled servicing can prevent unexpected breakdowns, which are costly and could disrupt the ripening schedule.

Safety and Compliance

- Safety Audits: Perform regular safety audits to ensure that the banana ripening chambers comply with all relevant health and safety regulations. This includes checking electrical systems for safety, ensuring that emergency exits are accessible, and that all safety signage is visible and legible.

- Record Keeping: Maintain detailed records of all maintenance activities, inspections, and repairs. Good record-keeping helps in troubleshooting problems and planning preventive maintenance, which is key to the smooth operation of any banana ripening plant.

- Training Staff: Ensure that all personnel involved in the operation of the banana ripening room are well-trained in both the operational procedures and safety protocols. Proper training reduces the risk of accidental damage to the equipment and enhances overall safety in the workplace.

By adhering to these maintenance tips, operators can ensure that their banana ripening chambers and banana ripening chamber process continue to operate efficiently and effectively, producing high-quality bananas while minimizing downtime and maximizing productivity. Regular maintenance not only supports operational excellence but also contributes to the longevity and profitability of the banana ripening plant.

Economic and Environmental Impact of PUF Panel-Based Banana Ripening Chambers

The use of PUF panels in banana ripening chambers significantly impacts both the economic viability and environmental sustainability of the banana ripening process. This section delves into the cost-benefit analysis of investing in PUF panel-based ripening chambers, explores the sustainability aspects of PUF panels, and discusses the role of technology in enhancing the efficiency of banana ripening.

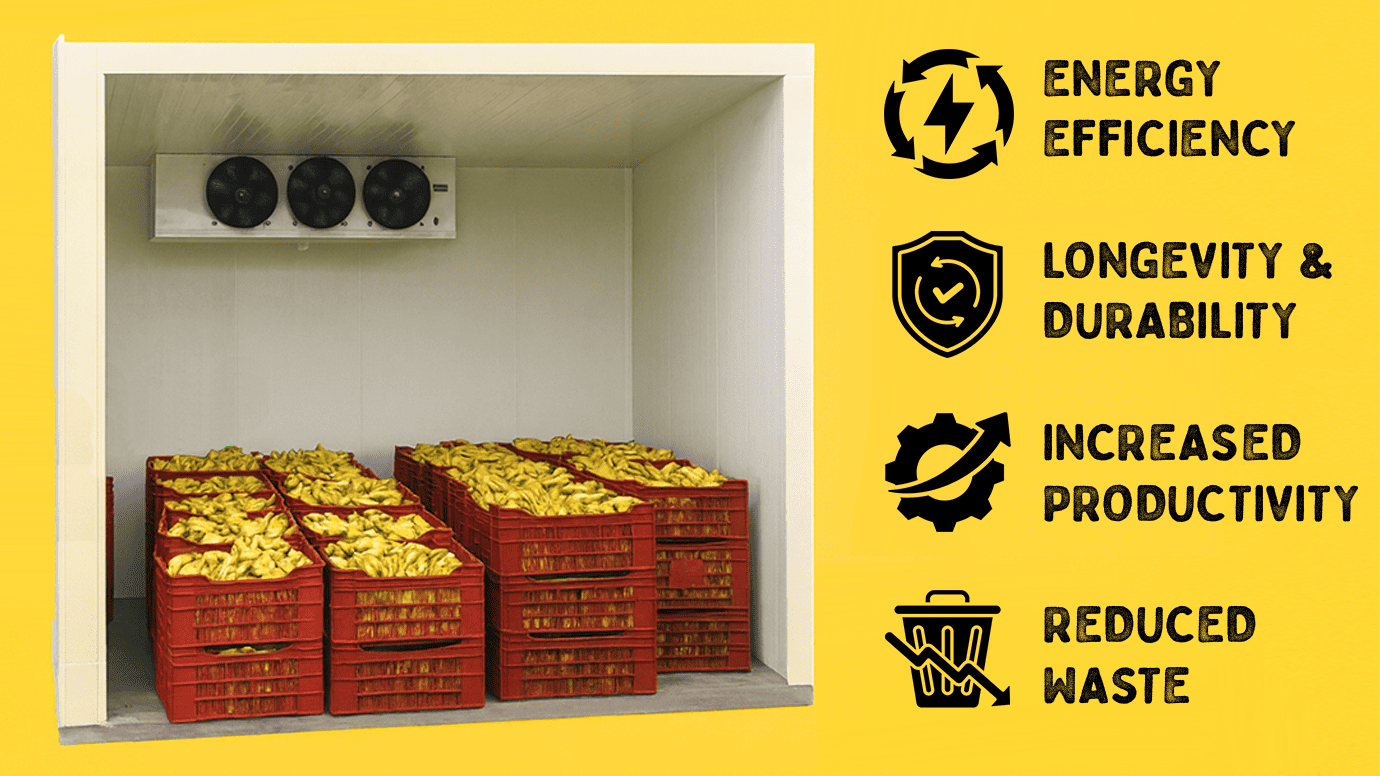

Cost-Benefit Analysis of PUF Panel-Based Banana Ripening Chambers

Investing in PUF panels for banana ripening chambers can yield substantial economic benefits. The initial cost of incorporating PUF panels into the banana ripening chamber design is offset by several factors:

- Energy Efficiency: PUF panels provide excellent insulation, significantly reducing the energy required for maintaining the necessary temperature and humidity levels in banana ripening rooms. This reduction in energy consumption can lead to considerable cost savings on utilities over the chamber's lifespan.

- Longevity and Durability: PUF panels are highly durable and resistant to corrosion, pests, and mold, reducing the need for frequent replacements or major repairs. This durability extends the lifespan of the banana ripening chambers, decreasing the long-term capital expenditures.

- Increased Productivity: The consistency in the banana ripening process afforded by the controlled environment of PUF panel-based chambers results in higher yields of market-ready bananas. This increase in productivity can significantly boost revenue, compensating for the initial setup costs.

- Reduced Waste: Enhanced control over ripening conditions leads to reduced spoilage and waste, thereby maximizing the use of harvested bananas. This efficiency not only improves profitability but also contributes to more sustainable operational practices.

Sustainability Aspects of Using PUF Panels

From an environmental perspective, PUF panels contribute to the sustainability of banana ripening chambers in several ways:

- Reduced Carbon Footprint: By improving energy efficiency, PUF panels help lower greenhouse gas emissions associated with electricity generation. This reduction is crucial for banana ripening plants aiming to minimize their environmental impact.

- Resource Conservation: The durability and effectiveness of PUF panels mean that fewer resources are needed for maintenance and repairs. This conservation of materials helps reduce the environmental burden associated with the production and disposal of building materials.

- Enhanced Thermal Efficiency: The superior insulation properties of PUF panels contribute to a more stable internal environment, which is essential for optimal ripening and energy use. This stability ensures that resources are utilized more efficiently, enhancing the overall sustainability of the banana ripening chambers.

Role of Technology in Enhancing Banana Ripening Efficiency

The integration of advanced technologies, such as the use of PUF panels and sophisticated climate control systems, plays a vital role in optimizing the ripening process in banana ripening chambers:

- Precision Control: Technological advancements enable precise control over temperature, humidity, and ethylene levels in banana ripening rooms, leading to more consistent and predictable ripening outcomes.

- Monitoring and Automation: Modern banana ripening chambers often include automated systems for monitoring and adjusting environmental conditions. These systems reduce the need for manual intervention, enhancing operational efficiency and reducing labor costs.

- Data Analytics: The use of data analytics in managing banana ripening chambers allows operators to optimize conditions based on real-time data, further enhancing efficiency and reducing waste.

In conclusion, the economic and environmental benefits of using PUF panels in banana ripening chambers are significant. These chambers not only foster more efficient and cost-effective banana ripening processes but also align with the growing need for sustainability in the agricultural sector. By leveraging advanced materials and technologies, banana ripening plants can achieve better outcomes both economically and environmentally.

Future Trends and Innovations in Banana Ripening Chambers

The field of banana ripening chambers is poised for significant advancements, driven by emerging technologies and continuous improvements in materials like PUF panels and overall banana ripening chamber design. These innovations are expected to further refine the efficiency, sustainability, and effectiveness of the banana ripening process.

Emerging Technologies in Banana Ripening

Innovative technologies are reshaping the way banana ripening chambers operate, offering new possibilities for enhancing ripening precision and operational efficiency:

- Smart Control Systems: Advanced IoT (Internet of Things) and AI (Artificial Intelligence) technologies are being integrated into banana ripening chambers to allow for smarter monitoring and control. These systems can autonomously adjust conditions based on real-time data, optimizing the ripening process and reducing energy consumption.

- Ethylene Application Innovations: New methods for ethylene application and control are emerging, which allow for more precise dosing and distribution. This precision helps ensure uniform ripening across all bananas in the banana ripening room, reducing waste and improving fruit quality.

- Advanced Sensors: The development of more sophisticated sensors that can monitor a range of environmental factors — including ethylene levels, temperature, and humidity — with greater accuracy. These sensors contribute to maintaining the ideal conditions required for optimal ripening within banana ripening chambers.

Potential Future Improvements in PUF Panel Formulations or Chamber Designs

The evolution of PUF panel technology and banana ripening chamber designs is critical to meeting future demands:

- Eco-Friendly PUF Panels: Research is ongoing into more sustainable PUF panel formulations that use bio-based polyols or incorporate recycled materials. These eco-friendly panels aim to reduce the environmental impact of the banana ripening chamber process without compromising insulation efficiency.

- Modular and Scalable Designs: Future banana ripening chamber designs might emphasize modularity and scalability, allowing for easier expansion or reconfiguration based on fluctuating market demands or technological upgrades.

- Integrated Energy Systems: There is potential for banana ripening chambers to integrate renewable energy sources, such as solar panels, directly into the chamber design. This integration could significantly reduce reliance on external power sources and decrease operational costs.

How Advancements Might Improve Ripening Processes in Banana Ripening Chambers

Advancements in technology and design are set to transform the banana ripening process in several ways:

- Increased Efficiency: New technologies and better materials will streamline the ripening process, making it faster and more energy-efficient. This efficiency will lower costs and increase the throughput of banana ripening plants.

- Enhanced Quality and Uniformity: : Improvements in environmental control and ethylene distribution will ensure that each banana ripens evenly, enhancing the overall quality and marketability of the fruit.

- Sustainability: With a greater focus on sustainability, future banana ripening chambers will likely be designed to minimize environmental impacts, using less energy and incorporating recycled or bio-based materials. Cost Reduction

- Cost Reduction: As technologies mature and become more integrated, the costs associated with installing and operating banana ripening chambers are expected to decrease, making these advanced systems accessible to a broader range of producers

FAQs:

Q. What are banana ripening chambers?

A. Banana ripening chambers are controlled environments designed to accelerate and regulate the ripening process of bananas. These chambers ensure that bananas ripen uniformly, achieving optimal texture and flavour.

Q. How do PUF panels enhance banana ripening chamber design?

A. PUF panels improve banana ripening chamber design by providing excellent insulation, maintaining consistent temperatures, and ensuring energy efficiency. Their properties are crucial for creating stable conditions needed for effective banana ripening.

Q. What role do PUF panels play in the ripening process of bananas in banana ripening chambers?

A. In the banana ripening process, PUF panels maintain the required temperature and humidity levels consistently in the banana ripening chambers, which is vital for effective ethylene-induced ripening of bananas.

Q. Why is temperature control important in banana ripening chambers?

A. Temperature control is critical in banana ripening chambers because it ensures that ethylene, the ripening agent, works effectively. Proper temperature management leads to uniform ripening of bananas.

Q. Can PUF panel-based banana ripening chambers reduce operational costs?

A. Yes, PUF panel-based banana ripening chambers can significantly reduce operational costs by minimizing energy consumption due to their high insulation properties.

Q. What are the sustainability benefits of using PUF panels in banana ripening chambers?

A. Using PUF panels in banana ripening chambers helps to reduce energy usage and carbon footprint, contributing to more sustainable practices in the banana ripening plant.

Q. How do smart technologies enhance the efficiency of banana ripening chambers?

A. Smart technologies like IoT and AI can monitor and automatically adjust conditions within banana ripening chambers, enhancing efficiency, reducing waste, and improving the overall quality of the ripened bananas.

Q. What future innovations are anticipated in banana ripening chamber design and process?

A. Future innovations in banana ripening chamber design may include more eco-friendly PUF panels, integrated renewable energy sources, and enhanced modularity for easier scalability.

Conclusion

The integration of PUF panels in banana ripening chambers has revolutionized the approach to banana ripening, bringing about substantial improvements in energy efficiency, cost-effectiveness, and fruit quality. These panels are central to the success of modern banana ripening chamber designs, offering superior insulation that helps maintain the precise conditions necessary for optimal ripening. The durability and thermal efficiency of PUF panels not only reduce operational costs but also enhance the uniformity and quality of the bananas ripened within these chambers. This makes them an invaluable asset in the banana ripening process.

The role of technology in agriculture, particularly in the construction and operation of banana ripening chambers, cannot be overstated. Technological advancements have paved the way for more controlled, predictable, and efficient agricultural processes. The use of innovative materials like PUF panels and the incorporation of advanced environmental control systems underscore the transformative impact of technology on the agricultural sector. These innovations ensure that agricultural practices not only meet current demands for efficiency and sustainability but are also scalable and adaptable to future challenges.

As the agricultural industry continues to evolve, the importance of staying at the forefront of technology and infrastructure development becomes increasingly clear. For those considering initiating or upgrading their banana ripening plant or banana ripening room, the use of high-quality PUF panels and modern chamber designs is essential.

If you are planning to start your own banana ripening chambers project or are looking to enhance your current facilities, consider reaching out to MAKS Engineering. Specializing in the construction and installation of PUF panels, MAKS Engineering can provide the expertise and high-quality materials necessary to ensure your project’s success. Whether you are at the initial planning stage or ready to implement advanced banana ripening chamber designs, MAKS Engineering is equipped to assist you in achieving a highly efficient and successful ripening process.

We encourage anyone in the agricultural sector looking to optimize their banana ripening process with the latest innovations in chamber technology to contact MAKS Engineering. Start laying the groundwork for a fruitful and prosperous venture in the world of banana ripening today.

To know more about PUF Panels, go to our dedicated page on PUF Panels.