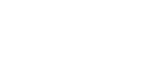

Normal PUF Panels vs Fire Retardant PUF Panels

Normal PUF Panels vs Fire Retardant PUF Panels: Choosing the Right Panels

In the world of modern construction, PUF panels have completely transformed how buildings are designed, insulated, and maintained. Whether it’s a commercial warehouse, a cold storage facility, a data center, or a residential project, these panels offer unmatched advantages in terms of energy efficiency, durability, and easy installation. One of the most significant reasons for their growing demand is their fire resistance PUF Panel, which makes them not only an insulation solution but also an important safety component.

PUF panels are available in different types, but the two most widely used are PUR PUF panels (Polyurethane Foam based) and PIR panels (Polyisocyanurate Foam based). Both are technically advanced and serve specific needs. PUR panels are generally referred to as “Normal PUF Panels” and are well‑known for their excellent thermal insulation and cost‑effectiveness. On the other hand, PIR PUF panels, also called Fire Retardant Panels, are specifically engineered to perform better in case of fire by reducing flame spread and providing additional protection. This makes them a reliable choice where higher safety standards are required.

The difference between a normal PUF panel and a fire retardant panel lies in how they are designed to handle fire. A normal PUF panel focuses on slowing down the passage of flames and heat, giving valuable time for occupants to respond. Meanwhile, a fire retardant panel, especially those made with PIR PUF panels, is chemically modified to resist ignition, produce less smoke, and form a protective char layer that further delays fire penetration.

For builders, architects, and facility managers, the key lies in choosing the right type of PUF panel based on project requirements. If the focus is on affordability and thermal insulation in environments with minimal fire risk, PUR panels are an excellent solution. However, for industries like pharmaceuticals, food processing, IT facilities, or cleanrooms where fire safety is critical, PIR panels with superior fire‑retardant properties are the preferred choice.

At MAKS Engineering, we specialize in providing expert installation services for both types of panels. Our goal is to help clients select the most suitable option — whether it’s the efficiency of PUR panels or the advanced protection of PIR PUF panels — ensuring that every project benefits from the perfect balance of safety, durability, and performance.

What are Normal PUF Panels?

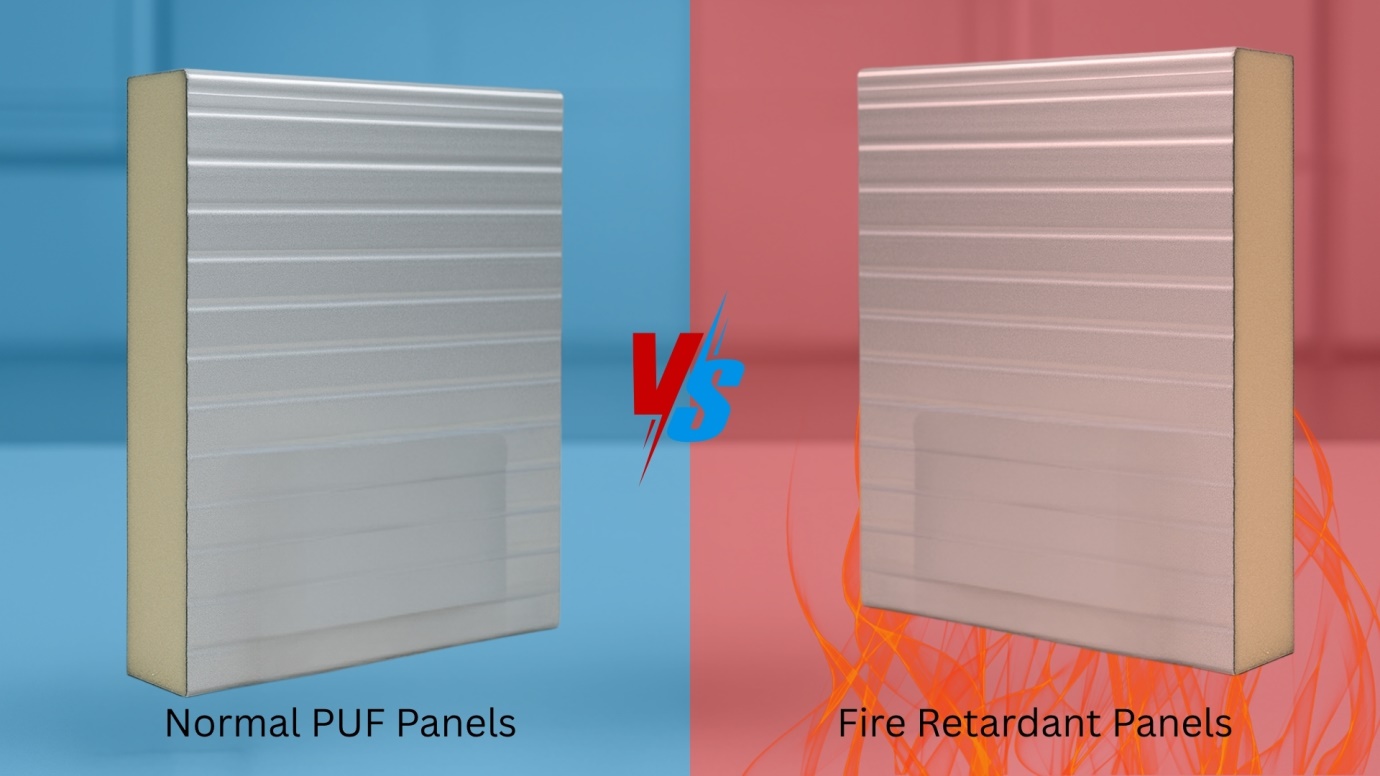

Normal PUF Panels are widely recognized as one of the most versatile building solutions in modern construction. These panels are designed with a polyurethane foam panel as the core material, which is sandwiched between two protective metal sheets. The result is a strong, lightweight, and durable building element that offers excellent insulation and structural benefits.

Structure of Normal PUF Panels

The construction of a PUR PUF panel is quite simple yet highly effective:

- Metal Skin Options: The outer layers are generally made of high quality steel sheets, available in two finishes:

- PPGI (Pre‑Painted Galvanized Iron) – durable and cost‑effective.

- PPGL (Pre‑Painted Galvalume) – offers superior corrosion resistance and long service life.

Want to understand the difference between PPGI and PPGL in more detail? Check out our in-depth blog on PPGI vs PPGL sheets to make an informed choice for your project.

- Foam Core: At the center lies the rigid polyurethane core, which provides insulation and strength. This is why pur sandwich panel construction is considered ideal for energy efficient and lightweight building solutions.

Key Features of Normal PUF Panels

Choosing PUR PUF panels for your project comes with several advantages:

- Excellent Thermal Insulation – The polyurethane foam panel core minimizes heat transfer, ensuring interiors stay cooler in summer and warmer in winter.

- Cost Effective and Lightweight – A PUR PUF panel delivers great performance at an affordable price, while being easy to transport and handle.

- Quick Installation – Pre fabricated design ensures fast installation, saving both time and labor costs.

- Dependable Safety – Although designed mainly for insulation, fire resistance ensures that it can still provide basic protection in low fire risk environments.

Typical Applications of Normal PUF Panels

Because of their practicality and affordability, PUR PUF panels are widely used in:

- Residential Buildings – for roofing, wall cladding, and partitioning.

- Warehouses – where cost effective insulation is required.

- Cold Storage Units – to maintain stable temperatures with minimal energy usage.

- General Industrial Sheds – where insulation and quick setup are more important than high fire ratings.

In short, PUR PUF panels are the perfect solution when you need efficient insulation, durability, and cost savings for projects in environments with minimal fire risks. Their simple yet effective pur sandwich panel structure makes them a go‑to choice for many industries and applications.

What are Fire Retardant PUF Panels?

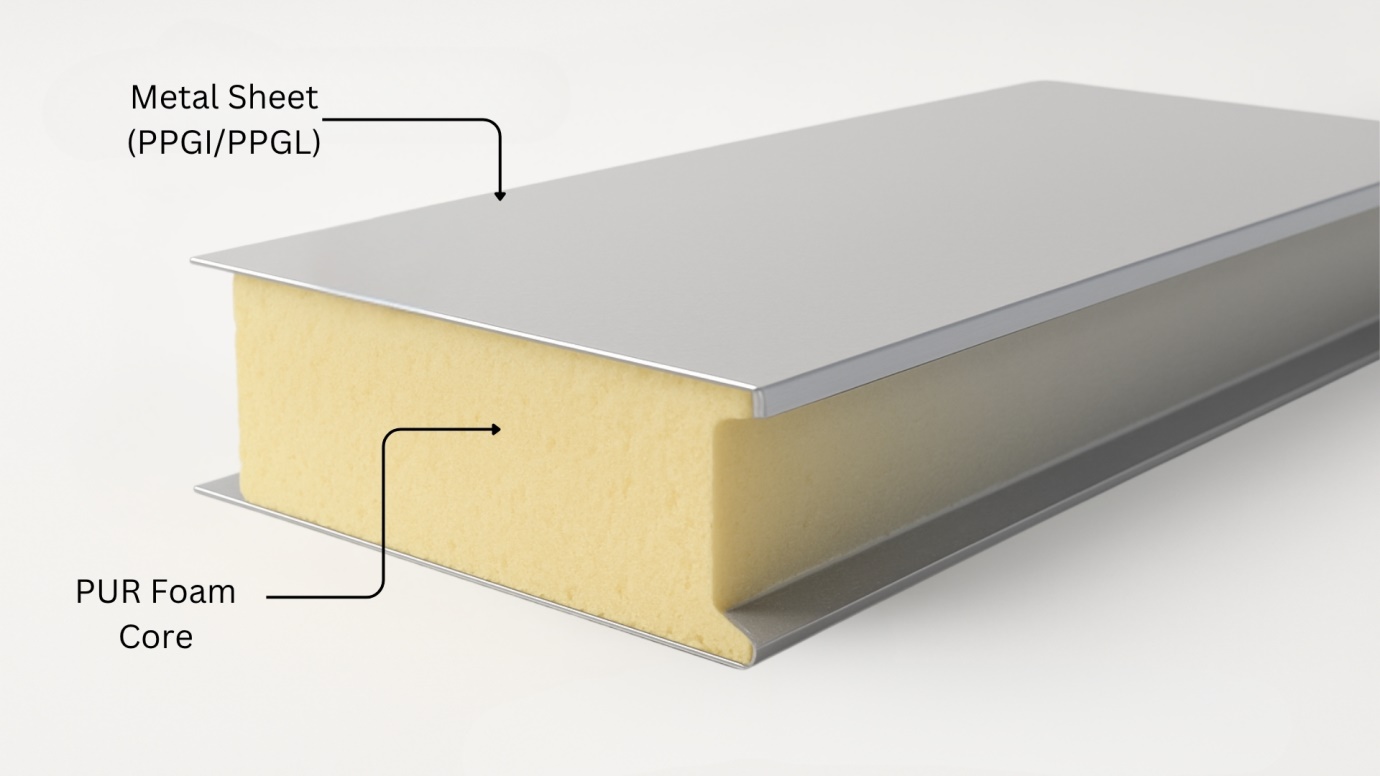

When projects demand higher levels of safety and compliance, Fire Retardant PUF Panels are the preferred solution. Unlike normal PUF panels that use PUR foam, these panels are designed with a PIR core (Polyisocyanurate). This makes a PIR panel more advanced in terms of fire safety, thermal performance, and long‑term durability. For industries where fire hazards are a major concern, fire retardant panels provide an added layer of protection without compromising on insulation.

Structure of Fire Retardant PUF Panels

Just like normal PUF panels, a PIR sandwich panel is built with two strong outer metal layers and an insulated foam core in the middle:

- Metal Skin Options:

- PPGI (Pre‑Painted Galvanized Iron): a popular option for cost efficiency.

- PPGL (Pre‑Painted Galvalume): provides superior corrosion resistance and longer lifespan.

- Foam Core: At the center is the PIR core, a chemically modified form of polyurethane known as a polyisocyanurate panel. This material is engineered to resist ignition, release less smoke, and create a char layer that slows down fire spread.

Key Features of Fire Retardant PUF Panels

Opting for PIR PUF panels brings several unique advantages:

- Higher Fire Resistance & Safety – A fire resistant panel with a PIR core significantly reduces flame spread and improves overall building safety.

- Better Thermal Stability – Insulated PIR panels can withstand higher operating temperatures than standard polyurethane panels.

- Long Term Durability – The rigid structure of a PIR composite panel makes it suitable for demanding industrial and commercial environments.

- Versatility – Available in different forms such as PIR core panels, PIR insulation panels, and PIR sandwich panels, offering flexibility for various applications.

Typical Applications of Fire Retardant PUF Panels

Thanks to their superior fire and insulation properties, fire retardant panels are widely used in:

- Data Centers – where electrical equipment requires enhanced protection.

- Pharmaceutical Units – for controlled, clean, and safe environments.

- Chemical Processing Units – where fire safety is a critical factor.

- Industrial Buildings & Warehouses – where long term durability and compliance are necessary.

- Clean Rooms – that demand both hygiene and safety.

In short, a PIR PUF panel is not just a panel but a high‑performance solution. Whether in the form of PIR core panels, these fire resistant panels are designed for environments where safety, compliance, and durability cannot be compromised.

Normal PUF Panels vs Fire Retardant PUF Panels – A Comparison

Both Normal PUF Panels and Fire Retardant PUF Panels have established themselves as reliable choices in the construction industry. The key lies not in deciding which one is better, but in identifying the best fit for your project’s requirements.

A PUR panel (Normal PUF) offers excellent thermal insulation, lightweight construction, and cost‑effectiveness — making it ideal for projects in low fire‑risk environments. On the other hand, a fire retardant panel with a PIR core offers superior fire resistance, higher durability, and enhanced protection in areas where safety standards are critical.

Key Differences at a Glance

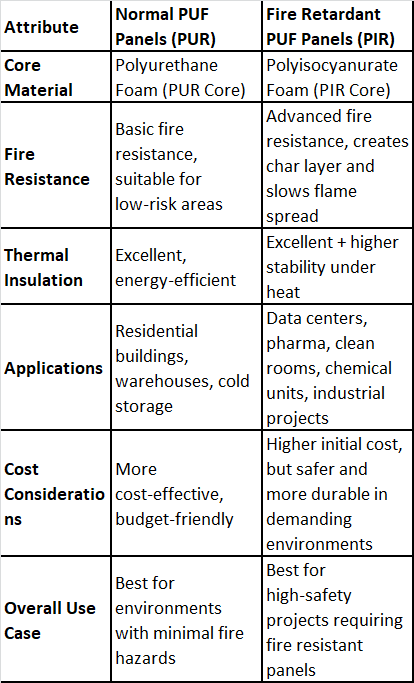

Attribute | Normal PUF Panels (PUR) | Fire Retardant PUF Panels (PIR) |

Core Material | Polyurethane Foam (PUR Core) | Polyisocyanurate Foam (PIR Core) |

Fire Resistance | Basic fire resistance, suitable for low‑risk areas | Advanced fire resistance, creates char layer and slows flame spread |

Thermal Insulation | Excellent, energy‑efficient | Excellent + higher stability under heat |

Applications | Residential buildings, warehouses, cold storage | Data centers, pharma, clean rooms, chemical units, industrial projects |

Cost Considerations | More cost‑effective, budget‑friendly | Higher initial cost, but safer and more durable in demanding environments |

Overall Use Case | Best for environments with minimal fire hazards | Best for high‑safety projects requiring fire resistant panels |

- If your project focuses on affordability and thermal insulation, then PUR sandwich panel can be the right choice.

- If your project requires compliance with fire resistance standards or is located in a fire sensitive environment, then a PIR PUF panel are the safer bet.

- Remember, both normal PUF panels and fire retardant panels serve unique purposes — it’s not about better or worse, but about the right solution for the right environment.

In summary, while a PUR panel excels in cost efficiency and insulation, a PIR panel ensures maximum protection where fire safety is non‑negotiable.

Which One Should You Choose?

Selecting between Normal PUF Panels and Fire Retardant PUF Panels depends entirely on the nature of your project. Both options are excellent in their own way — the key lies in understanding whether cost, insulation, or fire resistance is your top priority.

When to Choose Normal PUF Panels (PUR Panels)

If your project is in a low fire risk environment, a PUR panel can be the most cost effective and practical option. Built using polyurethane cores, these panels provide reliable insulation and structural strength at an affordable price point.

- Perfect for residential buildings, warehouses, and cold storage facilities.

- Best suited where fire resistance at a basic level is sufficient.

- Pur sandwich panel structures are lightweight, energy efficient, and quick to install.

- Ideal for projects where the focus is on thermal insulation and budget optimization rather than advanced fire resistance.

When to Choose Fire Retardant PUF Panels (PIR Panels)

If your project demands strict safety compliance, a fire retardant panel is the smarter choice. These panels are engineered for environments where fire safety cannot be compromised. With advanced fire resistance, they not only delay ignition but also slow down fire spread, ensuring more safety time.

- Best suited for pharma units, data centers, chemical industries, clean rooms, and industrial projects.

- PIR insulation panels are more thermally stable, making them durable in high temperature environments.

- The right choice when selecting a fire resistant panel that ensures long term safety and peace of mind.

Both PUR panels and PIR panels are perfect within their own scope of application. A PUR PUF panel provides excellent insulation and affordability, while a fire retardant panel offers enhanced safety and compliance. Choosing between them is not about which is better, but about aligning the panel type with your project requirements.

At MAKS Engineering, we help clients analyze their site conditions, risk factors, and budget to recommend the right solution — whether that’s a cost‑efficient pur sandwich panel or a high‑safety fire resistant panel.

FAQs:

Q. What is a polyurethane foam panel?

A. A polyurethane foam panel is a type of insulated construction material with a rigid PUR foam core that provides excellent thermal insulation and lightweight durability. These are commonly referred to as PUR PUF panels.

Q. What is the difference between a PUR panel and a PIR panel?

A. A PUR panel is made using polyurethane foam, while a PIR panel uses a modified foam known as polyisocyanurate. The PIR core provides higher fire resistance, making it suitable for demanding environments.

Q. Do Normal PUR panels provide fire protection?

A. Yes, Normal PUR panels offer basic fire resistance. They are suitable for projects with minimal fire hazards such as warehouses, cold storage, and residential applications.

Q. Why are PIR PUF panels considered fire retardant panels?

A. PIR PUF panels are categorized as fire retardant panels because their PIR core chemically resists ignition, forms a char layer, and provides better flame spread control than traditional PUR foam.

Q. How does a PIR sandwich panel differ from a PUR sandwich panel?

A. A PIR sandwich panel uses polyisocyanurate foam, which offers higher fire resistance, better thermal stability, and greater durability compared to a pur sandwich panel.

Q. Where are PUR PUF panels most commonly used?

A. PUR PUF panels are widely used in residential projects, warehouses, cold storage units, and areas where fire risk is minimal.

Q. Where are PIR insulation panels typically installed?

A. PIR insulation panels are used in projects requiring strict compliance with fire standards, such as pharmaceutical plants, clean rooms, data centers, and chemical processing units.

Q. Can I use PIR PUF panels for cold storage applications?

A. Yes, PIR PUF panels are excellent for cold storage because they provide both superior insulation and fire resistance, ensuring safety along with energy efficiency.

Q. Which is more cost effective: PUR panels or PIR panels?

A. PUR panels are more budget friendly and provide good insulation. PIR panels may cost more initially but offer long term value through advanced fire resistant panel performance and durability.

Q. What metal options are available for PUR and PIR panels?

A. Both pur panels and pir panels are available with PPGI (Pre Painted Galvanized Iron) and PPGL (Pre Painted Galvalume) finishes, ensuring strength, corrosion resistance, and longevity.

Conclusion

In the evolving world of modern construction, both Normal PUF Panels and Fire Retardant PUF Panels have proven to be highly reliable building solutions. Each serves a different purpose — a polyurethane foam panel is ideal for cost‑sensitive projects, while a PIR core panel offers advanced fire protection where safety is critical.

A PUR panel delivers excellent insulation, lightweight construction, and affordability, making it the perfect solution for residential buildings, warehouses, and cold storage. On the other hand, a PIR panel, whether in the form of a PIR sandwich panel, provides superior fire resistance, longer durability, and compliance with strict fire safety standards.

Key Takeaways

- PUR Panels: Affordable, energy‑efficient, and ideal for projects with minimal fire risks.

- PIR Panels: Advanced fire retardant panels designed for industries where fire safety cannot be compromised.

Both panel types are excellent choices — it’s not about better or worse, but about selecting the right solution based on project requirements.

At MAKS Engineering, we specialize in the installation of both PUR and PIR panels, helping clients choose the most effective option for their specific needs. Whether you’re planning with polyurethane foam panels for insulation or seeking the extra protection of a fire resistant panel, our team ensures precision installation and long‑term performance.

Ready to decide which PUF panel is right for your project? Contact us today for expert guidance, customized solutions, and professional installation services tailored to your requirements.

To learn more about different types of PUF panels and our expert installation services, feel free to visit our Home page.